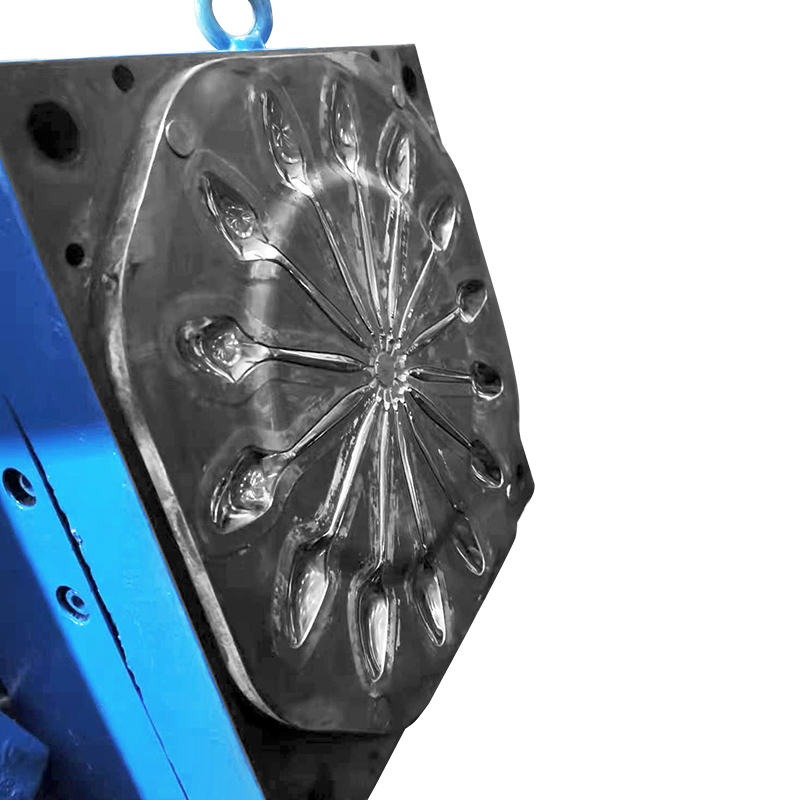

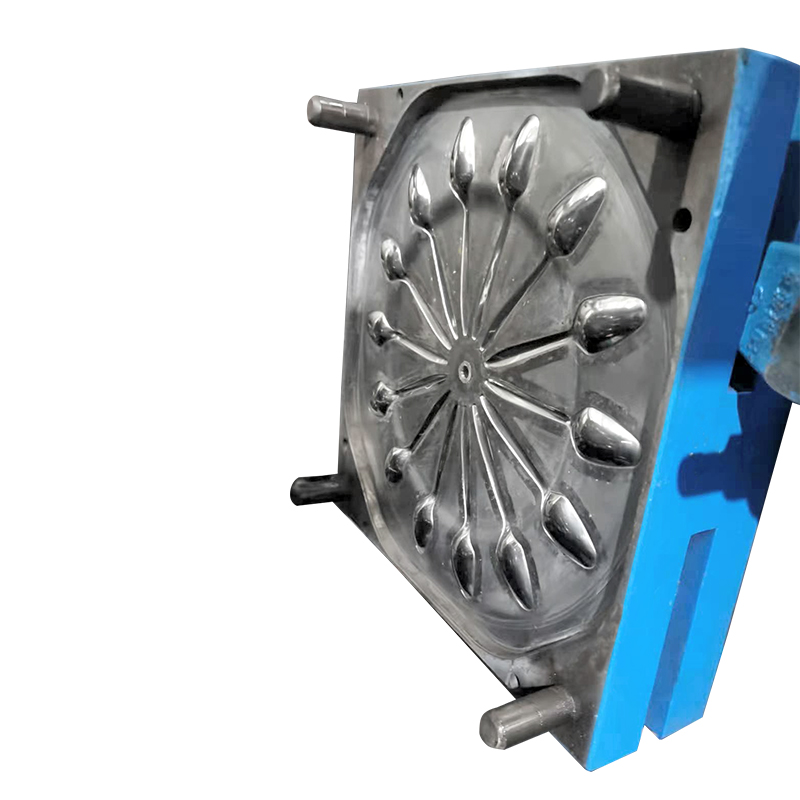

Product Description:

We pride ourselves on offering high-quality used disposable plastic spoon moulds that provide value for our customers. These moulds have undergone rigorous inspection and refurbishment processes to ensure they meet our stringent quality standards.

Our used stool mould is designed to meet various manufacturing requirements. These moulds come in different types and designs, ensuring versatility for various stool models. With quick delivery times and significantly lower costs compared to new moulds, our used stool moulds are an attractive option for manufacturers looking to optimize their production processes.

Quality and Condition

We take great care in selecting our used stool moulds to ensure they remain in good condition. Each mould is thoroughly inspected and refurbished if necessary, guaranteeing that it can still run for a long time. This meticulous process ensures that our used stool moulds maintain high standards of performance and durability.

Cost-Effectiveness

One of the primary advantages of our used stool mould is the cost savings. By choosing a used mould, you can save up to 30% compared to the price of a new mould. This significant reduction in cost does not come at the expense of quality, making used stool moulds an economically wise choice for manufacturers.

Quick Delivery

Given the high demand for efficient production solutions, our used stool moulds can be delivered quickly. Located in Taizhou, a city renowned for its mould and plastic industries, we have access to a vast network of suppliers. This strategic location enables us to offer prompt delivery times, ensuring that your production lines remain uninterrupted.

Customization and Versatility

Our used stool moulds are available in various designs and configurations to cater to different manufacturing needs. Whether you require a specific style or size, we have a range of options to choose from. This versatility allows you to select a mould that good fits your production requirements, ensuring nice efficiency.

Durability and Longevity

Despite being pre-owned, our used stool moulds are built to last. We ensure that each mould undergoes a rigorous renewal process to replace any worn parts and verify its functionality. This attention to detail ensures that our used stool moulds can provide reliable service for an extended period.

Customer Satisfaction

We prioritize customer satisfaction by ensuring that every used stool mould we sell meets strict quality standards. Our commitment to thorough inspections and refurbishments means that you can trust in the performance and reliability of our products. Additionally, our customer service team is always ready to assist with any inquiries or support you may need.

In summary, our used stool mould offers a cost-effective, reliable, and environmentally friendly solution for your manufacturing needs. With various designs and quick delivery times, these moulds provide the flexibility and efficiency required to keep your production lines running smoothly. By choosing our used stool mould, you are making a smart investment that balances quality with affordability.

English

English Español

Español عربى

عربى