Product Description:

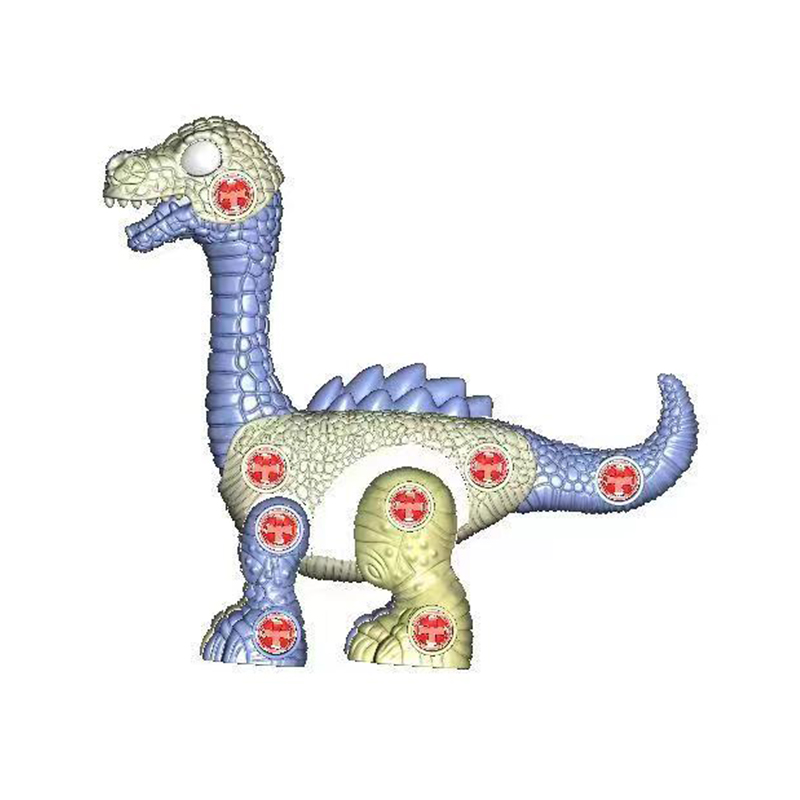

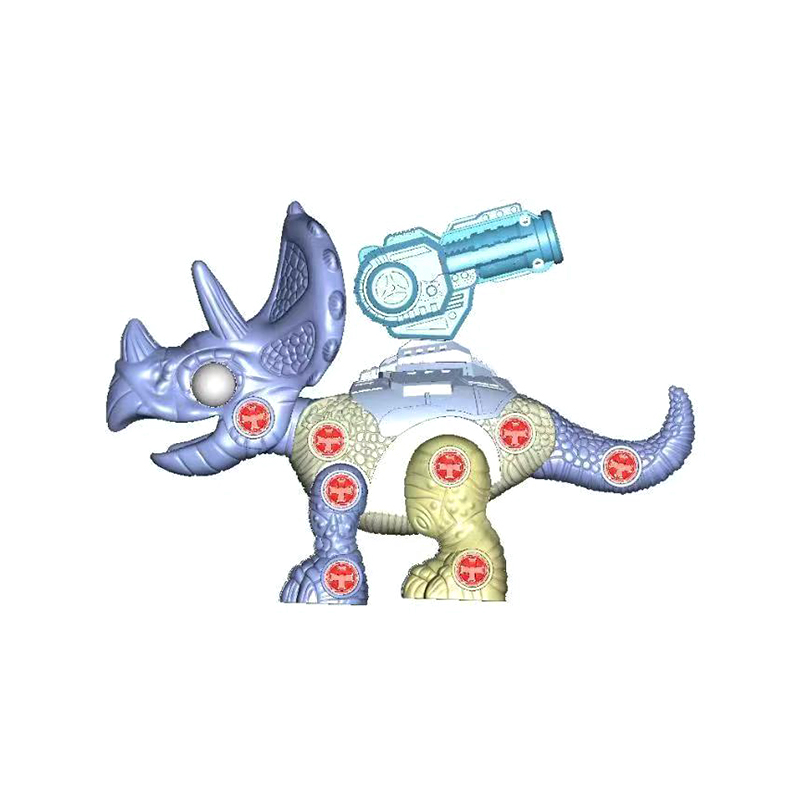

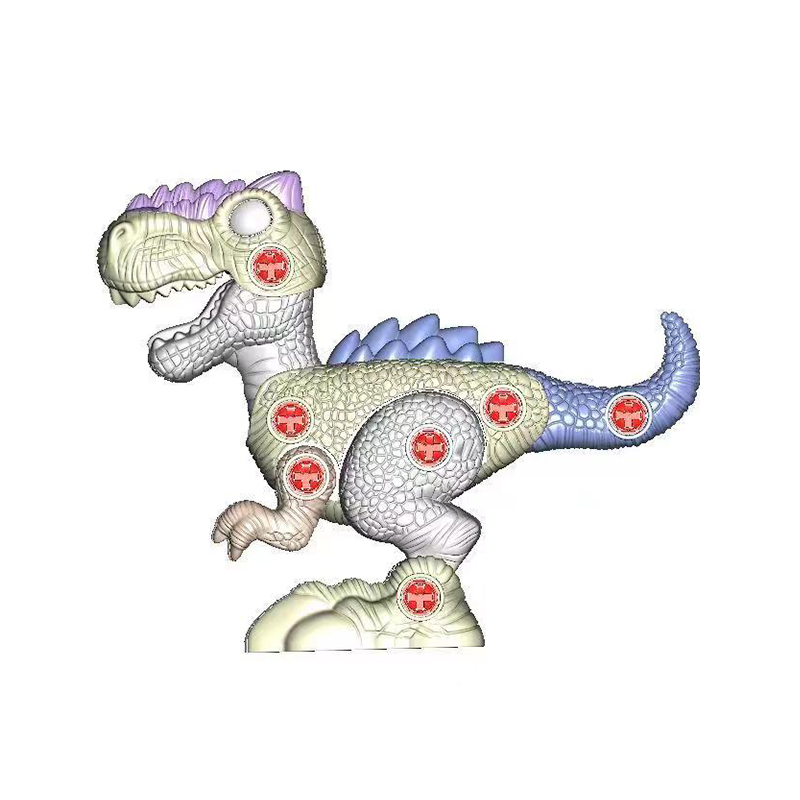

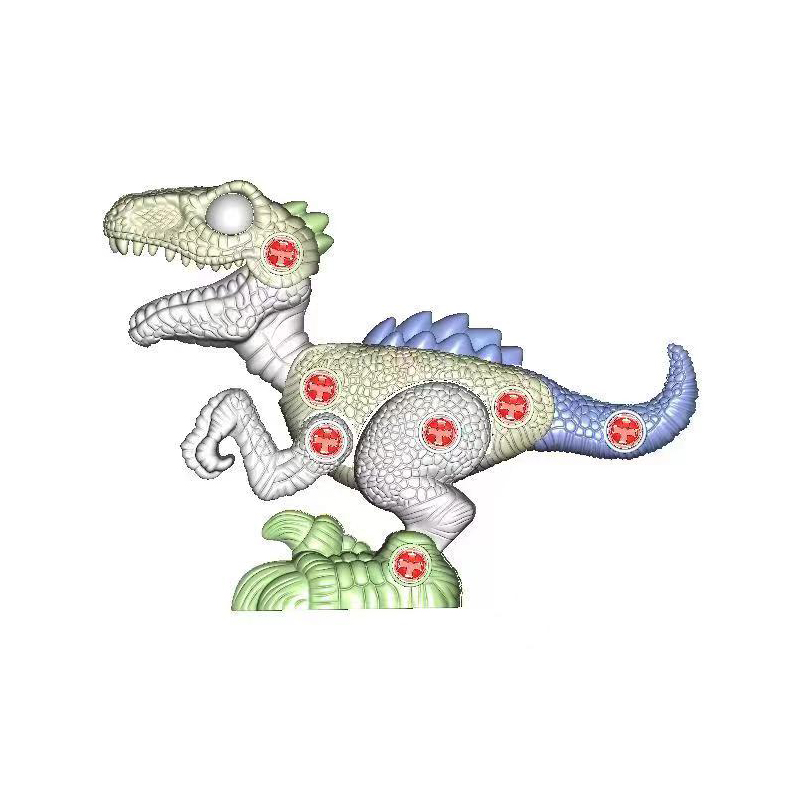

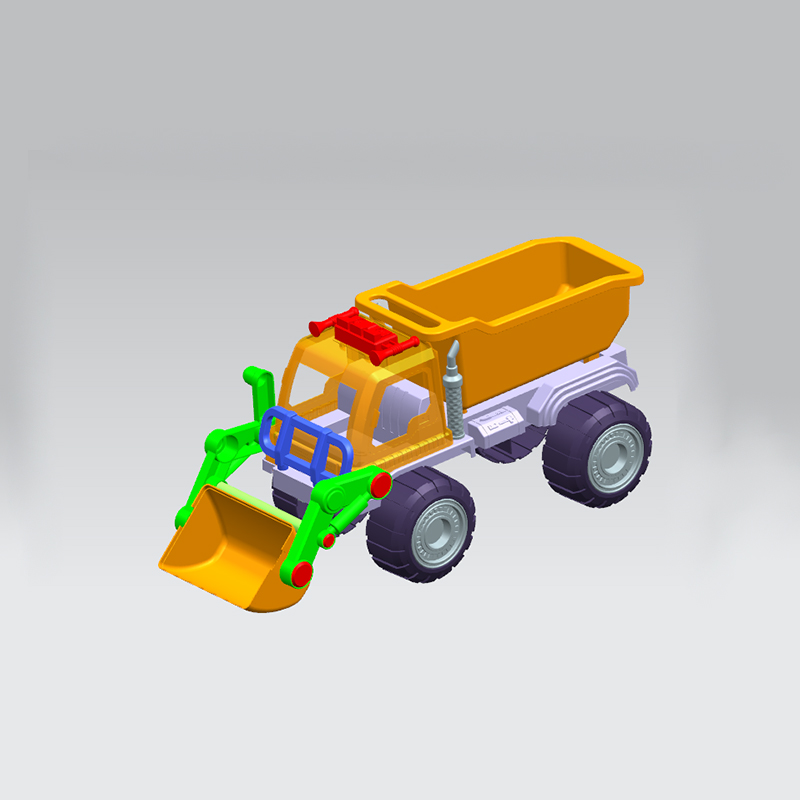

When it comes to crafting plastic dinosaur toys, precision and quality are paramount. At our manufacturing facility, we prioritize greatness in every step of the process.

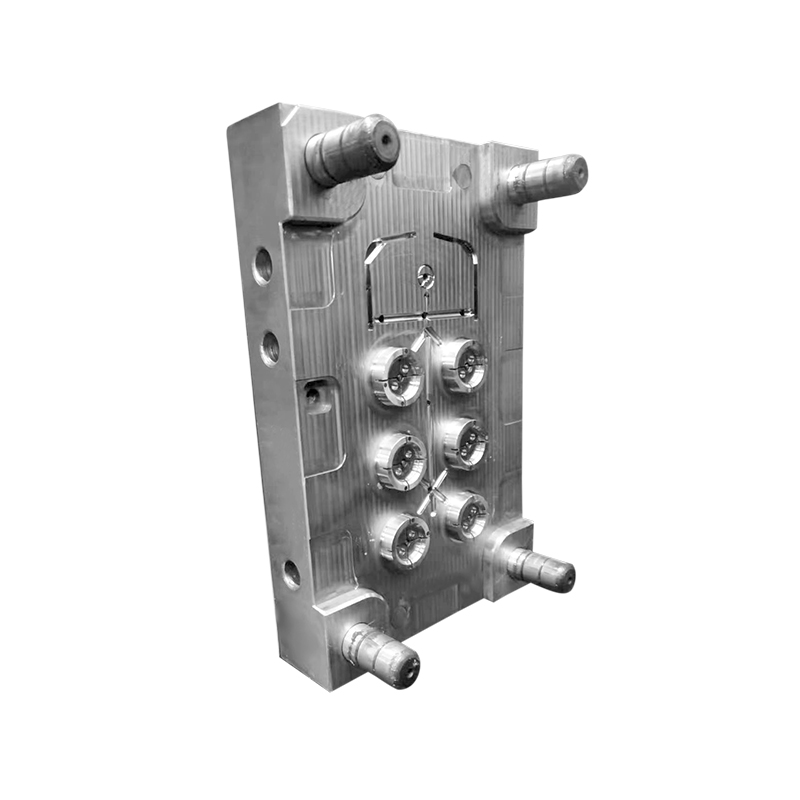

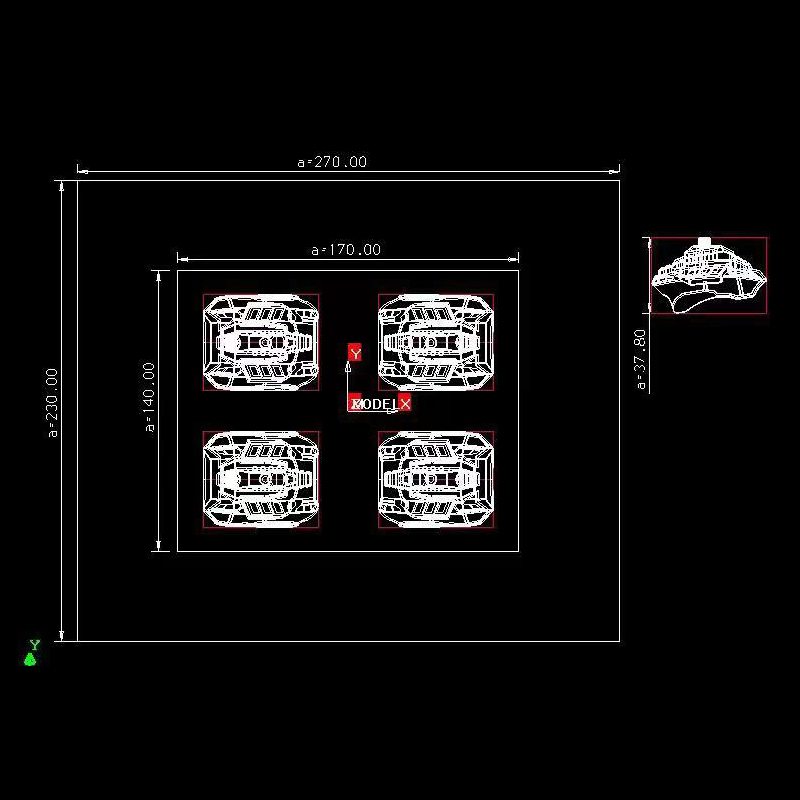

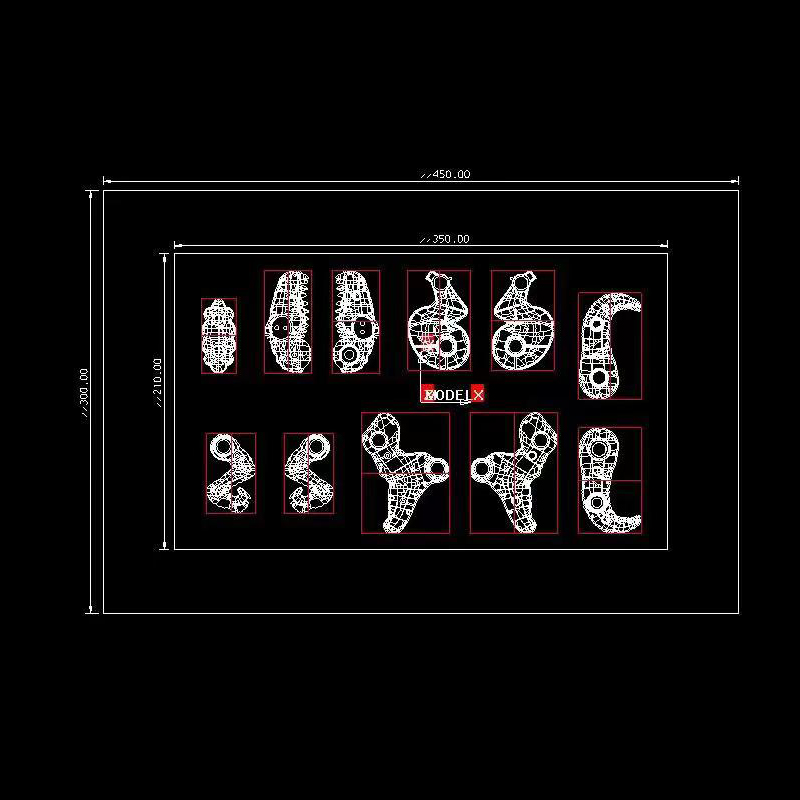

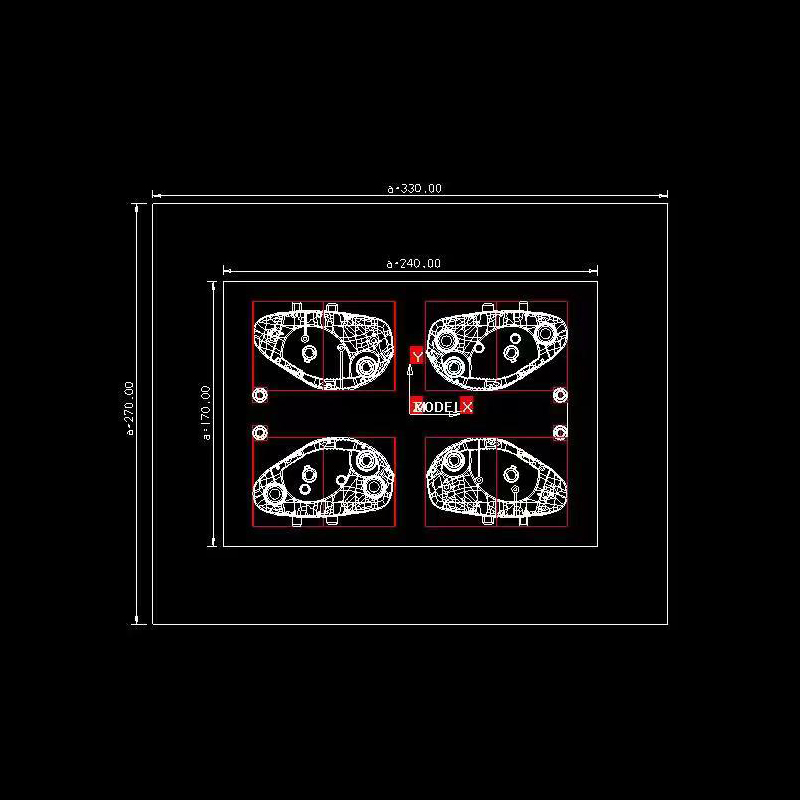

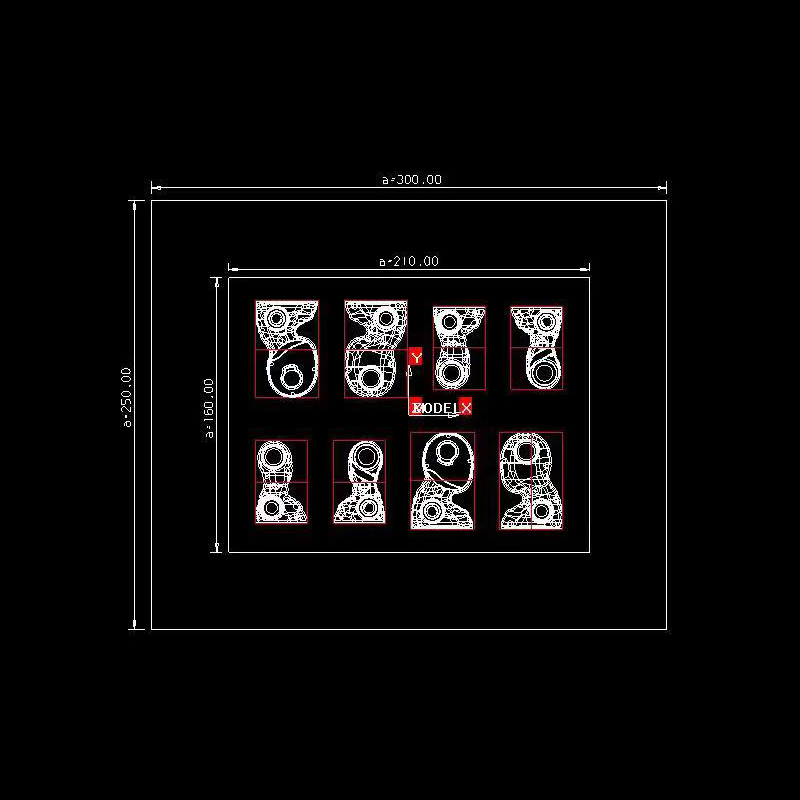

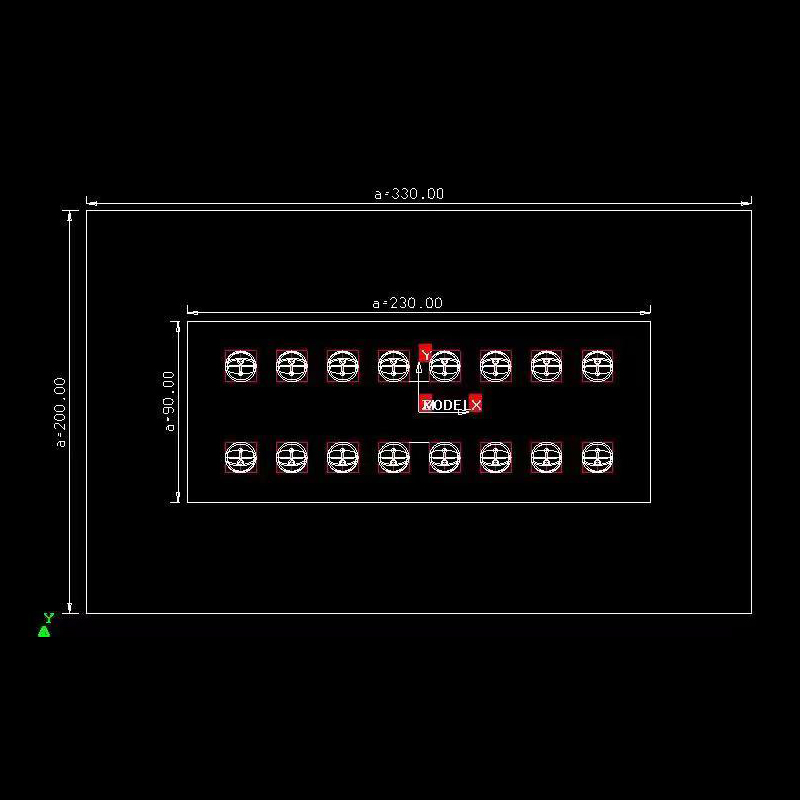

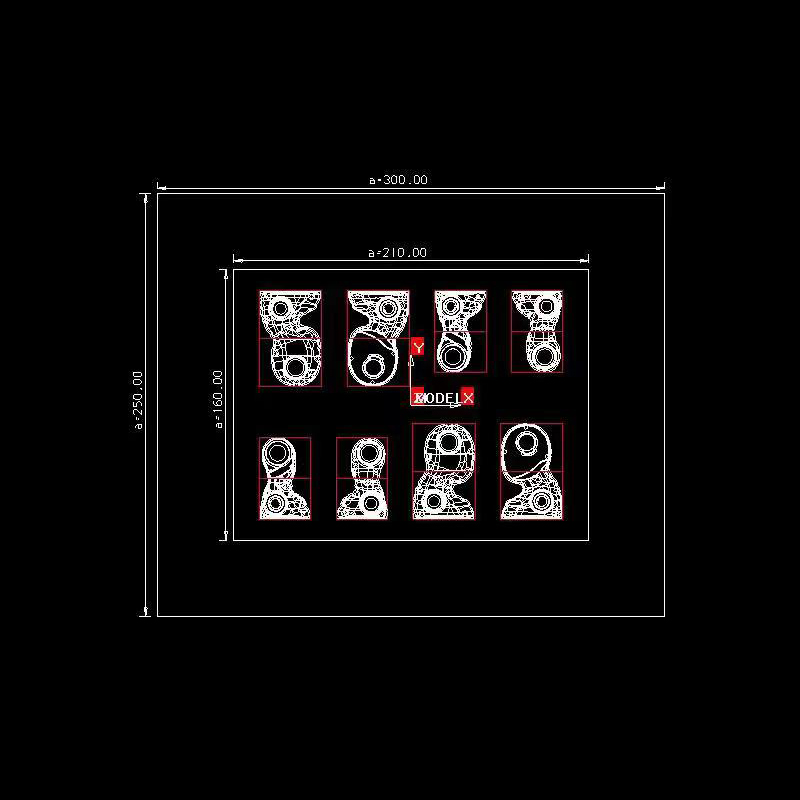

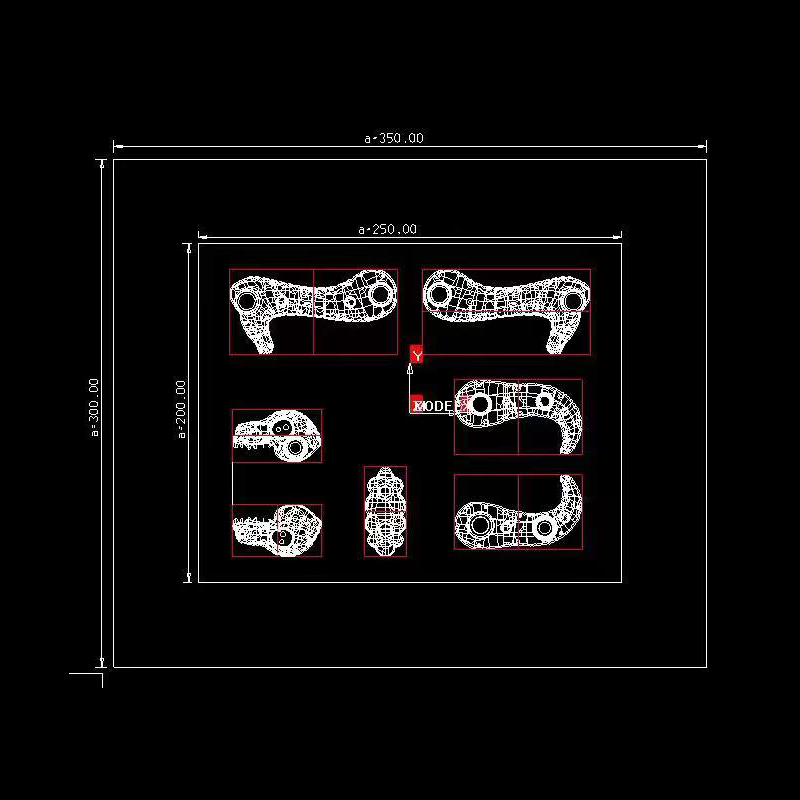

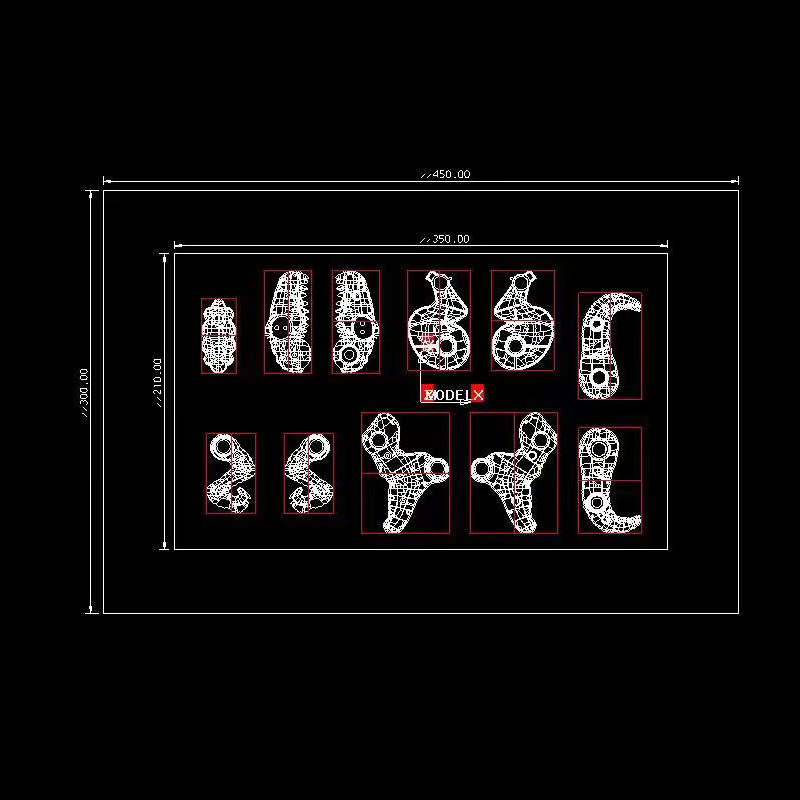

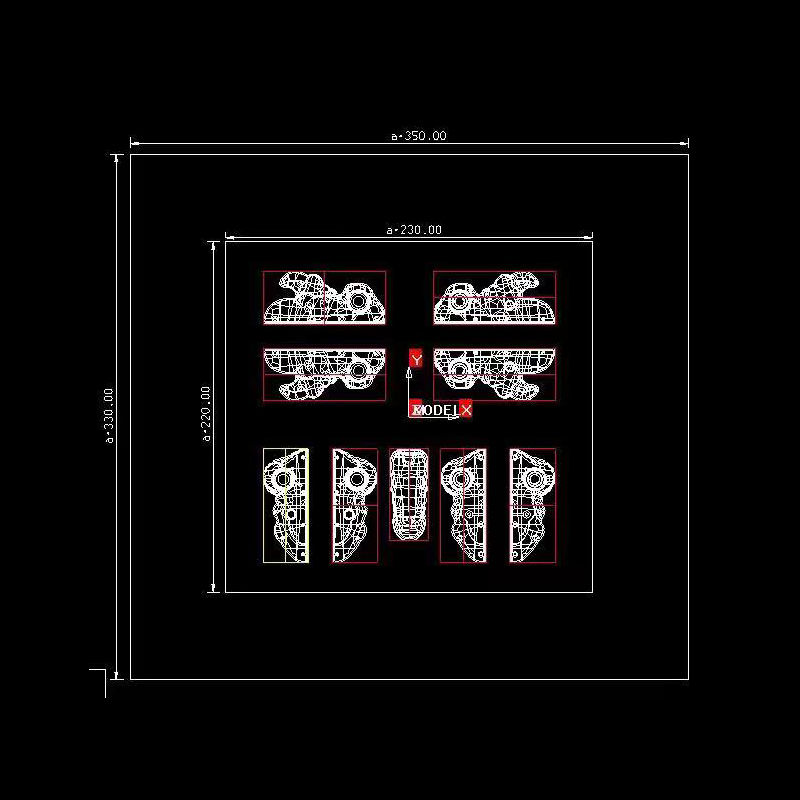

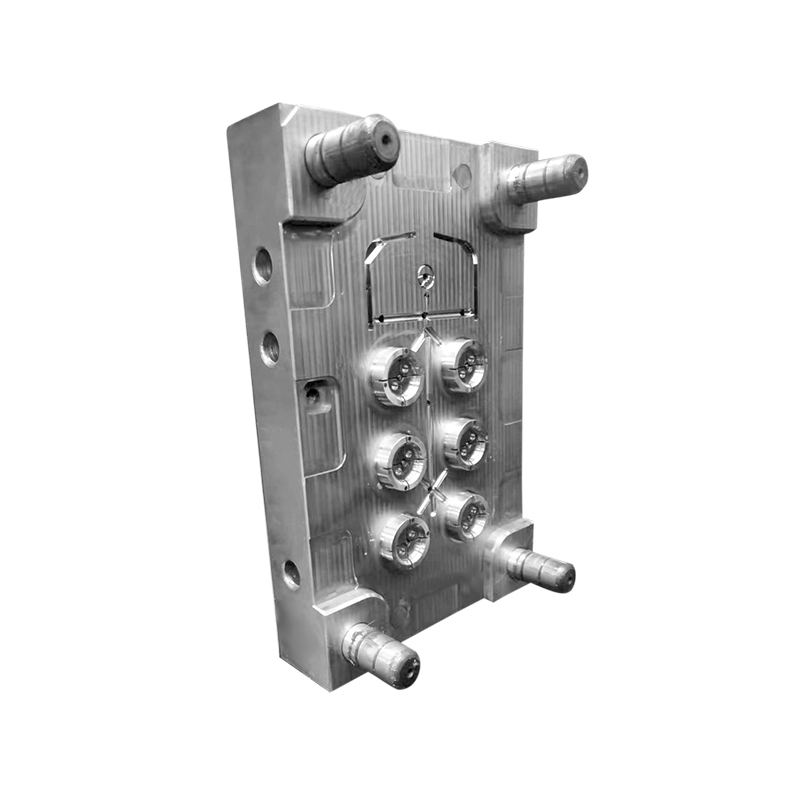

Our Toy Moulds are a good solution for all your needs. Designed with precision and made from high-quality materials, these moulds ensure that each toy produced is of high standard.

Key Features

High Precision and Detail:

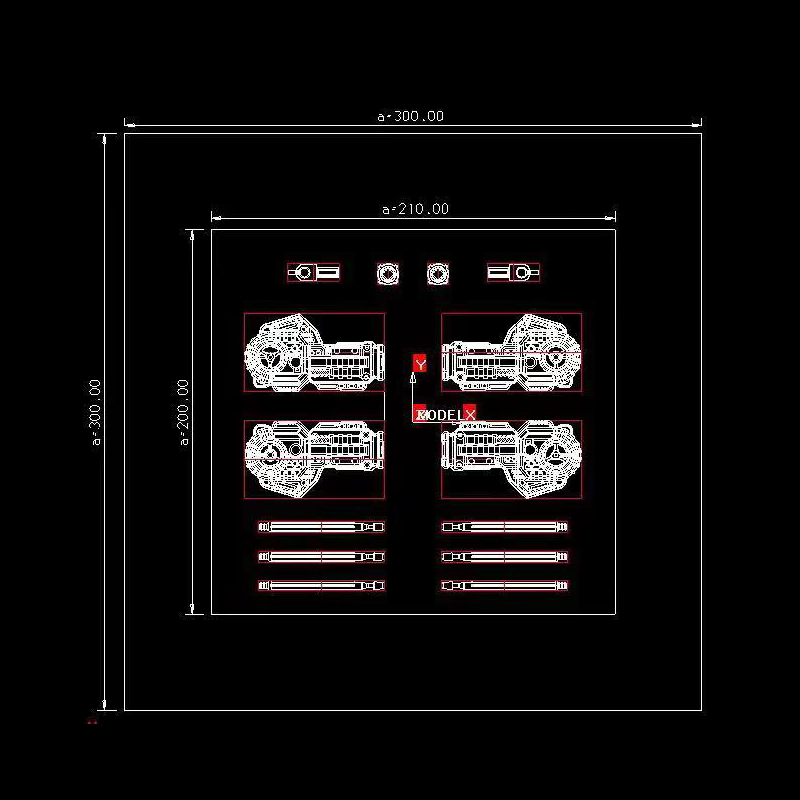

Our Toy Moulds are crafted with meticulous attention to detail. They capture every nuance and feature of the toy design, ensuring that the final product is an exact replica of your vision. The high precision allows for intricate designs, making it possible to create toys with complex shapes and fine details.

Durable Materials:

Durability is a key aspect of our Toy Moulds. Made from robust materials such as hardened steel and high-grade aluminum, these moulds can withstand the rigors of mass production. This ensures a longer lifespan, making them a cost-effective choice for manufacturers looking to produce large quantities of toys.

Versatility:

Our Toy Moulds are highly versatile and can be used with a variety of materials including plastic, resin, and silicone. This flexibility allows you to experiment with different textures and finishes, giving you the freedom to create unique and innovative toys that stand out in the market.

Benefits of Using Our Toy Moulds

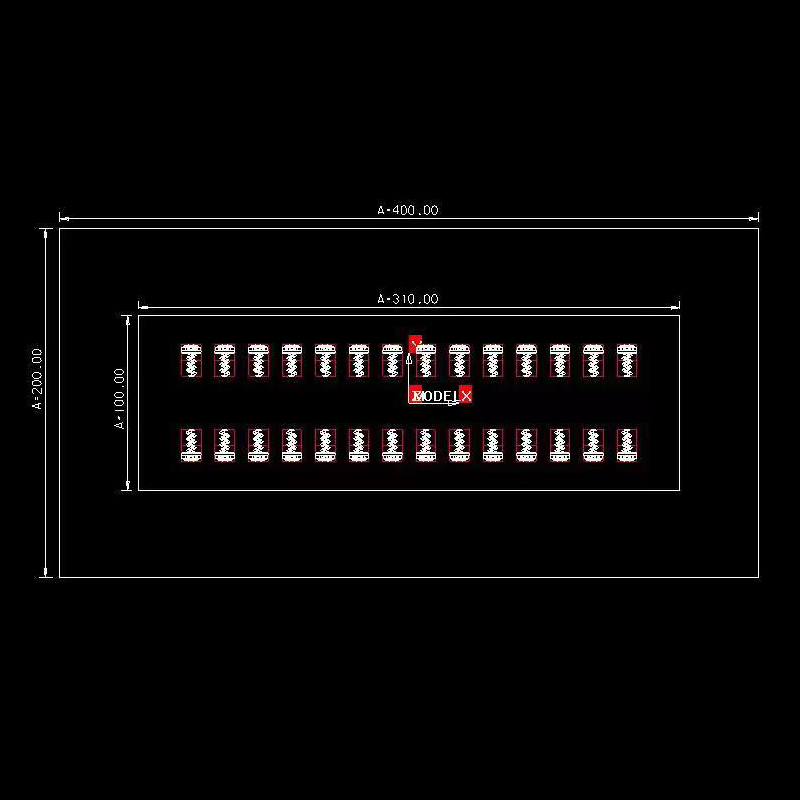

Efficiency in Production:

Using our Toy Moulds streamlines the manufacturing process. They are designed for easy use and quick release, which significantly reduces production time and increases efficiency. This allows you to meet high demand without compromising on quality.

Cost-Effective Solution:

Investing in our Toy Moulds is a smart financial decision. The durable materials and precise construction mean fewer replacements and repairs, to lower long-term costs. Additionally, the ability to produce toys at a faster rate boosts your overall productivity and profitability.

Customization Options:

We offer customized Toy Moulds to meet your specific needs. Whether you need a unique shape, a particular size, or special features, our team of experts can create a mould that matches your requirements nicely. This customization capability allows you to bring your creative ideas to life with ease.

Our Toy Moulds are the ideal choice for anyone looking to produce high-quality, detailed, and durable toys. Whether for small-scale projects or large manufacturing operations, our Toy Moulds provide the reliability and greatness you need to succeed in the competitive toy industry. Explore our range today and discover how our Toy Moulds can transform your production process.

English

English Español

Español عربى

عربى