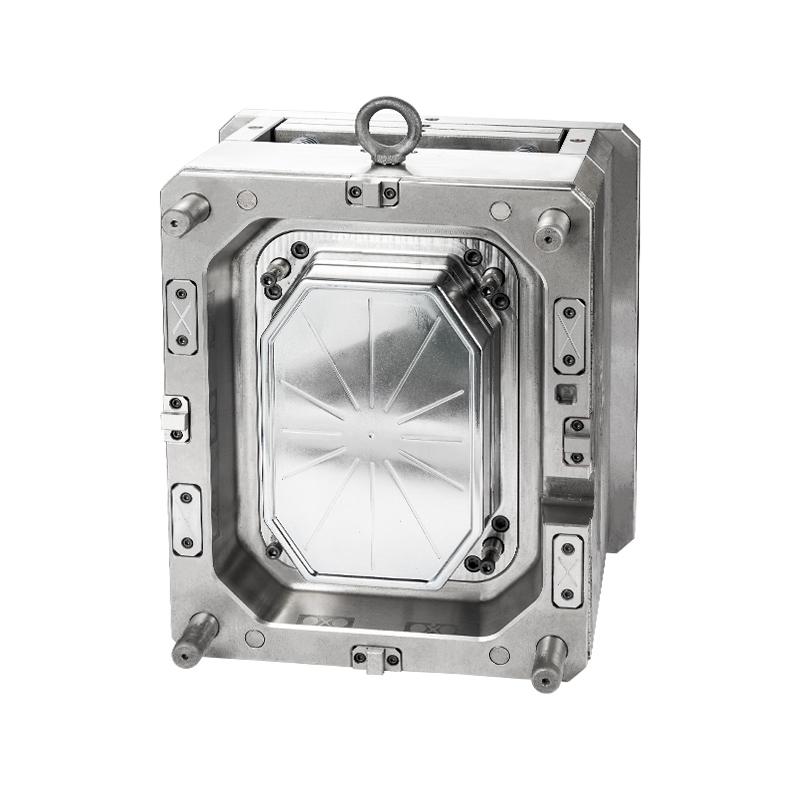

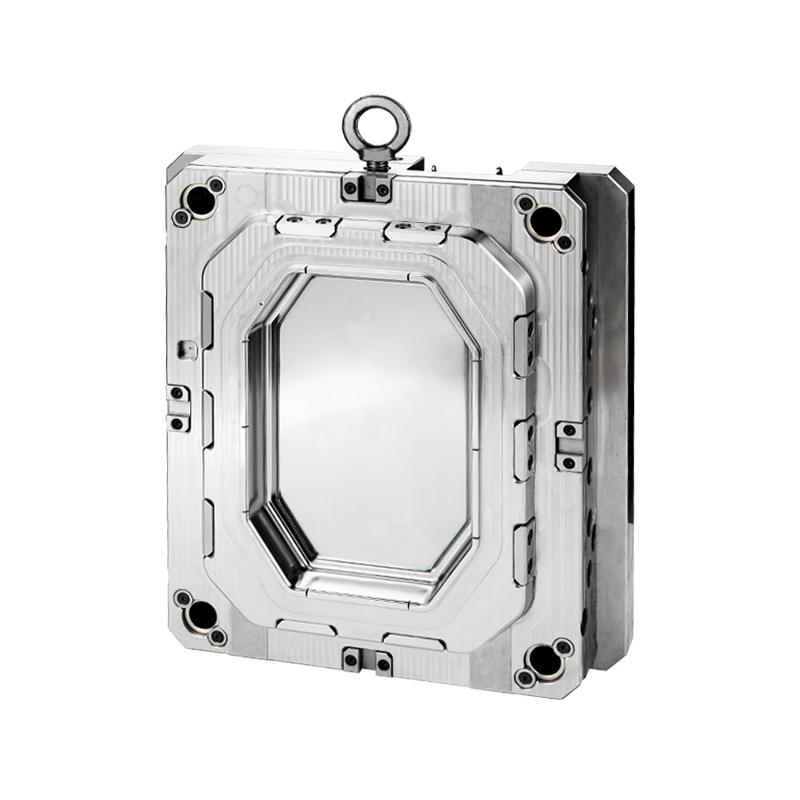

Product Description:

Our expertise lies in crafting high-quality Plastic Thin Wall Food Container Moulds, tailored to meet diverse production needs.

Thin Wall Mould, a critical innovation in the plastic injection moulding industry, is specifically designed for manufacturing lightweight, high-precision plastic components with ly thin walls. These moulds are widely used in various sectors, including packaging, medical devices, and consumer electronics, where the demand for durable yet lightweight plastic parts is high.

Product Features

The primary feature of Thin Wall Mould is its ability to produce extremely thin-walled components with uniform thickness. This is achieved through advanced engineering techniques and the use of high-quality materials. The moulds are designed to withstand high injection pressures and fast cooling times, ensuring that each product is consistent and free from defects. The precision of Thin Wall Mould makes it ideal for creating intricate designs and complex geometries that are often required in high-performance applications.

Material and Durability

Thin Wall Moulds are constructed from premium-grade steel, which enhances their durability and lifespan. The materials used in these moulds are carefully selected to resist wear and tear, even under the demanding production conditions. This ensures that the moulds maintain their accuracy and performance over extended periods, providing a reliable solution for high-volume production.

Applications

Thin Wall Moulds are versatile and can be utilized in various industries. In the packaging industry, they are used to produce containers, lids, and other items that require a balance of strength and lightness. In the medical field, Thin Wall Moulds are essential for creating disposable medical devices and packaging. The electronics industry benefits from these moulds in the production of housings and components that require precise dimensions and reduced weight.

In conclusion, Thin Wall Mould offers a combination of precision, durability, and efficiency, making it an invaluable tool in modern manufacturing. Its ability to produce lightweight yet strong plastic components with thin walls makes it a choice across multiple industries, driving innovation and cost-effectiveness in production processes.

English

English Español

Español عربى

عربى