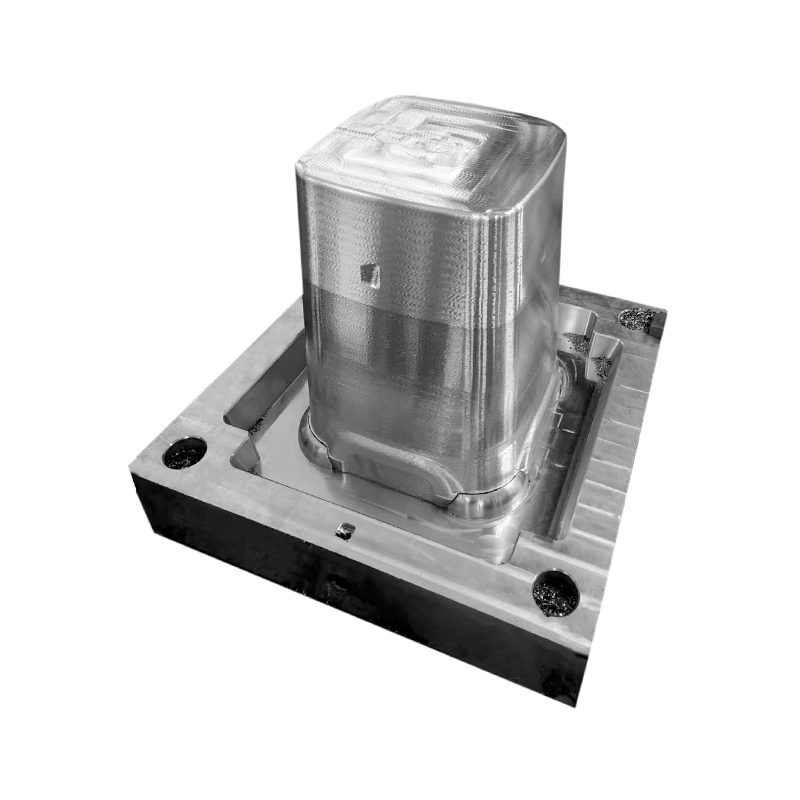

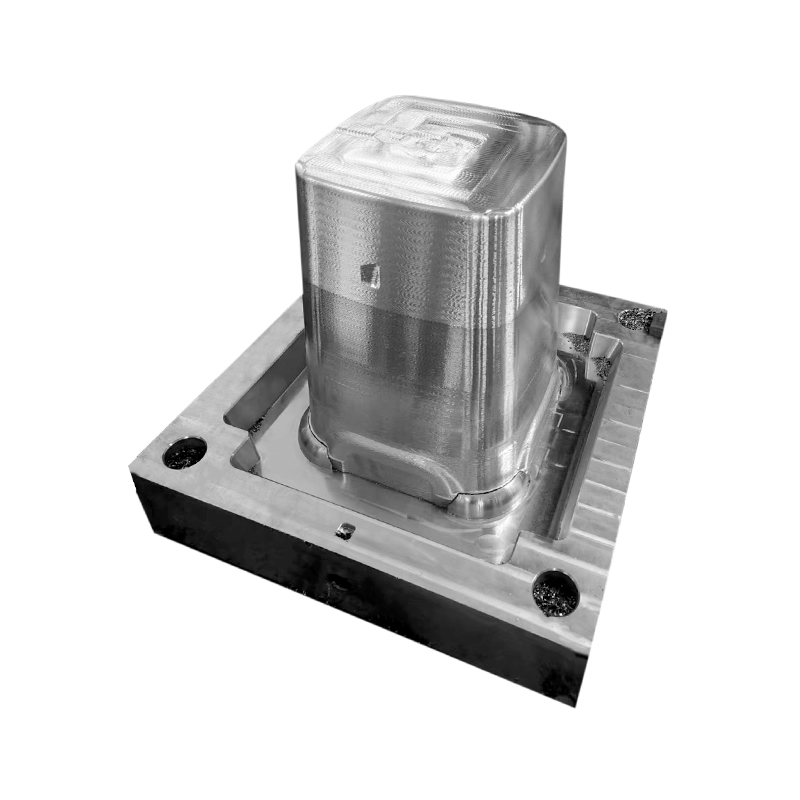

Product Description:

Our company specializes in crafting high-quality Durable Plastic Stool Injection Moulds tailored to meet diverse customer needs. including customization options, material selection, and nice design considerations.

Stool moulds, in essence, are meticulously crafted structures designed to shape raw materials into exquisite stool designs. These moulds come in a variety of forms, catering to diverse stool designs ranging from fewerist to intricately detailed.

Features of Stool Moulds:

Durable Construction:

Crafted from high-quality materials such as stainless steel or aluminium, stool moulds exhibit durability and longevity. This robust construction withstands the rigours of continuous usage, offering a prolonged service life with fewer maintenance requirements.

Enhanced Customization:

With modular components and adjustable parameters, stool moulds facilitate enhanced customization options. Manufacturers can tailor mould specifications to suit specific design preferences and production constraints, thereby fostering creativity and innovation in stool design.

Smooth Surface Finish:

Stool moulds are carefully designed to provide a smooth surface without defects such as burrs or surface irregularities. This smooth finish enhances the aesthetic appeal of the final product while providing a tactile experience that exudes quality craftsmanship.

Advantages of Stool Moulds:

Streamlined Production Processes:

By automating and standardizing production procedures, stool moulds streamline manufacturing processes, thereby increasing throughput and reducing production times.

Cost Efficiency:

The efficiency gains achieved through stool mould utilization translate into cost savings for manufacturers. Reduced material wastage, enhanced productivity, and minimized rework contribute to overall cost efficiency and improved profitability.

Consistent Quality Assurance:

Stool moulds uphold stringent quality standards, ensuring consistency in product quality across all production batches. This instils confidence in consumers, fostering brand loyalty and reputation in the marketplace.

Reduced Manual Intervention:

Automated production processes enabled by stool moulds minimize the reliance on manual labour, thereby mitigating labour-related challenges such as labour shortages and skill gaps.

stool moulds represent a cornerstone of modern manufacturing, offering a myriad of advantages and fulfilling the essential needs of buyers in today's market. As the demand for innovative stool designs continues to rise, stool moulds will remain indispensable tools for manufacturers seeking to thrive in the competitive landscape.

English

English Español

Español عربى

عربى