Product Description:

As a manufacturer specializing in plastic moulds, we take pride in our craftsmanship and dedication to quality. Our plastic bucket moulds are designed to meet high standards of durability, functionality, and safety.

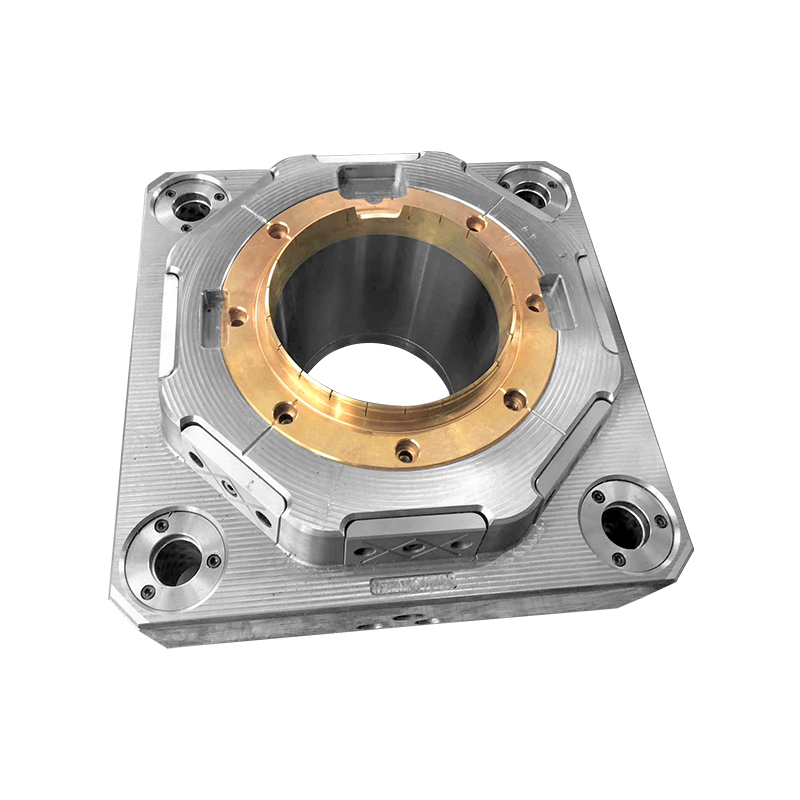

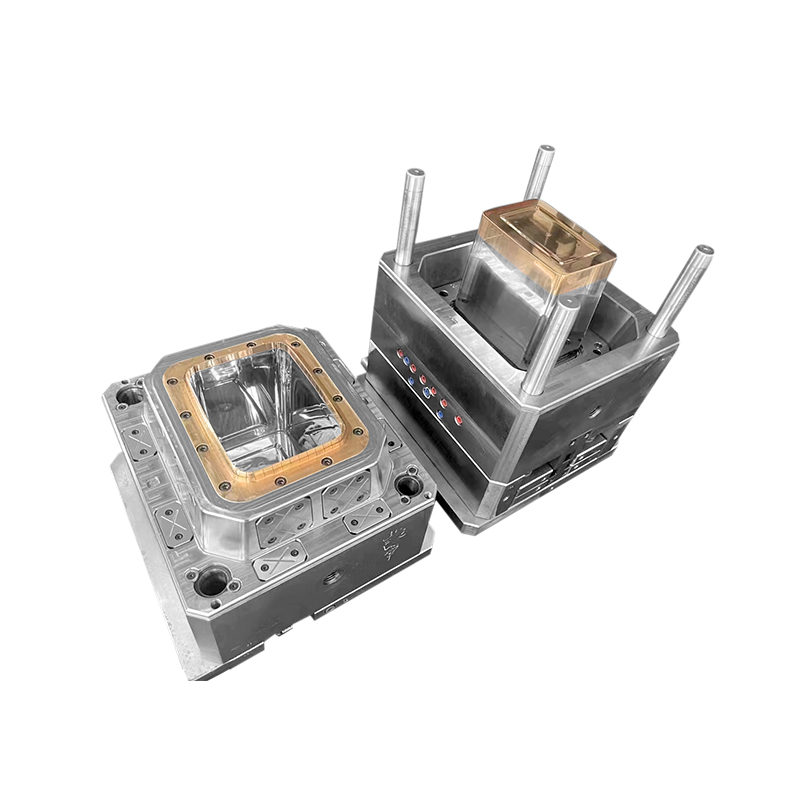

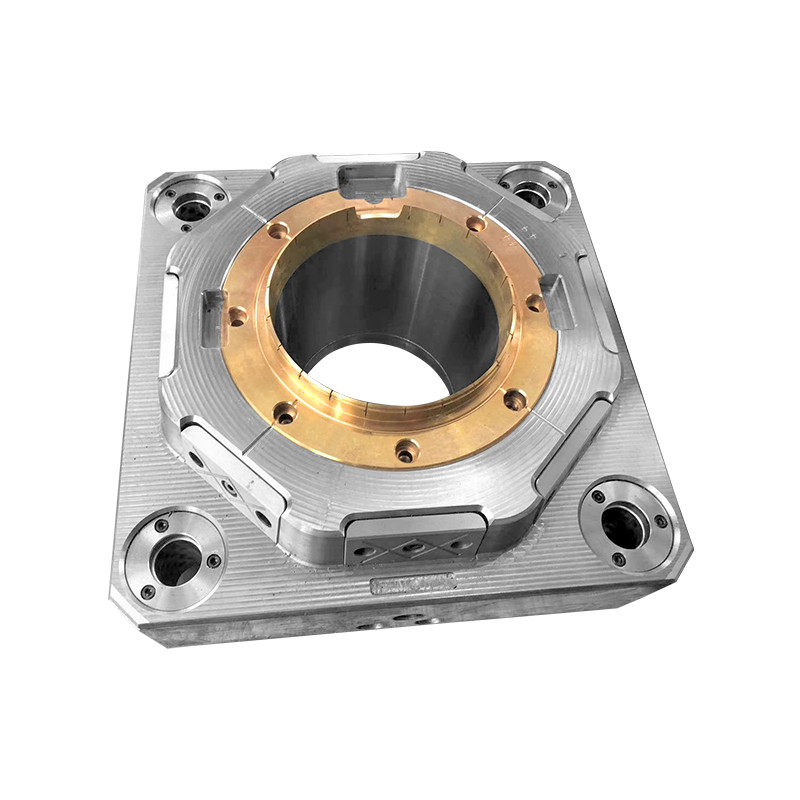

In the realm of manufacturing, the production of pails and buckets is a specialized field that requires precision and efficiency. At the heart of this process lies the Pail Bucket Mould, a critical tool that enables the creation of these versatile containers in large quantities.

To comprehend the practicality of pail bucket moulds, one must grasp their fundamental design and function. These moulds, typically crafted from high-quality materials such as steel or aluminium, are meticulously engineered to create containers of varying shapes, sizes, and specifications. Employing advanced manufacturing techniques like injection moulding, these moulds enable the mass production of pails, buckets, and similar containers with precision and efficiency.

Versatility Across Industries:

The practicality of pail bucket moulds manifests prominently in their versatility across a multitude of industries. From agriculture to construction, food processing to chemical manufacturing, these moulds cater to diverse needs, producing containers tailored to specific requirements. In agriculture, for instance, pail bucket moulds yield durable containers for storing seeds, fertilizers, and harvested crops. Similarly, in construction, these moulds fabricate sturdy buckets essential for transporting cement, mortar, and other building materials.

Durability and Reliability:

One of the key practical advantages of pail bucket moulds lies in the durability and reliability of the containers they produce. Engineered to withstand harsh environmental conditions, heavy loads, and rigorous usage, these moulded containers offer longevity and resilience.

Customization Capabilities:

In addition to their standard applications, pail bucket moulds offer extensive customization capabilities, further augmenting their practicality. Manufacturers can tailor the design, size, colour, and features of the containers to meet specific customer preferences and industry requirements. This flexibility enables businesses to differentiate their products, cater to niche markets, and address evolving consumer demands effectively.

From their role in streamlining manufacturing processes to their contribution to cost savings, durability, and environmental sustainability, these moulds epitomize efficiency, reliability, and innovation. As industries evolve and consumer demands evolve, the versatility and customization capabilities of pail bucket moulds position them as indispensable assets in the modern manufacturing landscape, driving progress, and facilitating growth.

English

English Español

Español عربى

عربى