The Role of Plastic Injection Mould in Modern Industrial Manufacturing

In the manufacturing world, precision and efficiency are paramount, especially when producing high-quality products in large quantities. Multi-cavity cutlery mould have become a crucial tool in this process, and the role of plastic injection moulding in modern industrial manufacturing is equally significant.

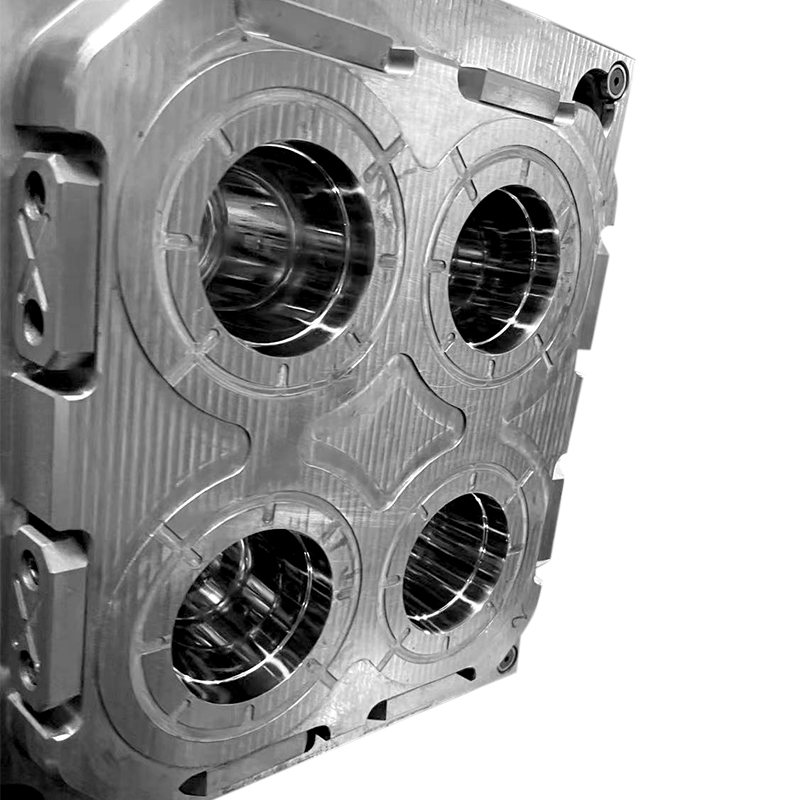

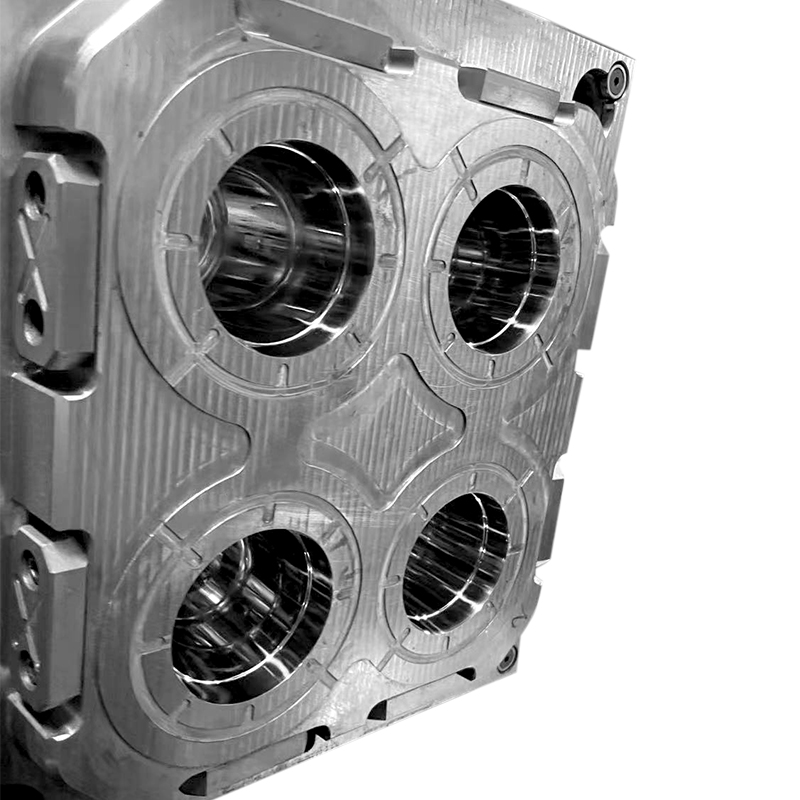

Characteristics of Multi-Cavity Cutlery mould

A Multi-Cavity Cutlery Mould Manufacturer specializes in creating mould designed to produce multiple cutlery items in a single production cycle. These mould offer several key characteristics that enhance production efficiency and product consistency.

High Production Capacity: One of the primary features of Muti-Cavitiy Cutlery Mould Manufacturer is their ability to produce multiple items simultaneously. Unlike single-cavity mould, which create only one piece per cycle, multi-cavity mould can produce several cutlery pieces at once. This capability significantly increases production output and efficiency, making it ideal for meeting large-volume demands.

Consistent Quality: Muti-Cavitiy Cutlery Mould Manufacturer are engineered to ensure uniformity in the cutlery produced. By using a single mould to create multiple items, manufacturers can maintain consistent dimensions, shapes, and finishes across all pieces. This uniformity is crucial for maintaining high standards of quality and ensuring that each item meets the required specifications.

Cost-Effectiveness: Although the initial investment in Muti-Cavitiy Cutlery Mould Manufacturer can be higher compared to single-cavity mould, they offer cost advantages over time. The ability to produce multiple items per cycle reduces the overall cost per unit, making them a cost-effective choice for large-scale production. The efficiency of multi-cavity mould also contributes to lower manufacturing costs and improved profitability.

Enhanced Production Efficiency: Muti-Cavitiy Cutlery Mould Manufacturer are designed to optimize the injection moulding process. They allow for faster cycle times and reduced production downtime, as multiple items are produced in each cycle. This efficiency helps to streamline the manufacturing process, reduce times, and improve overall productivity.

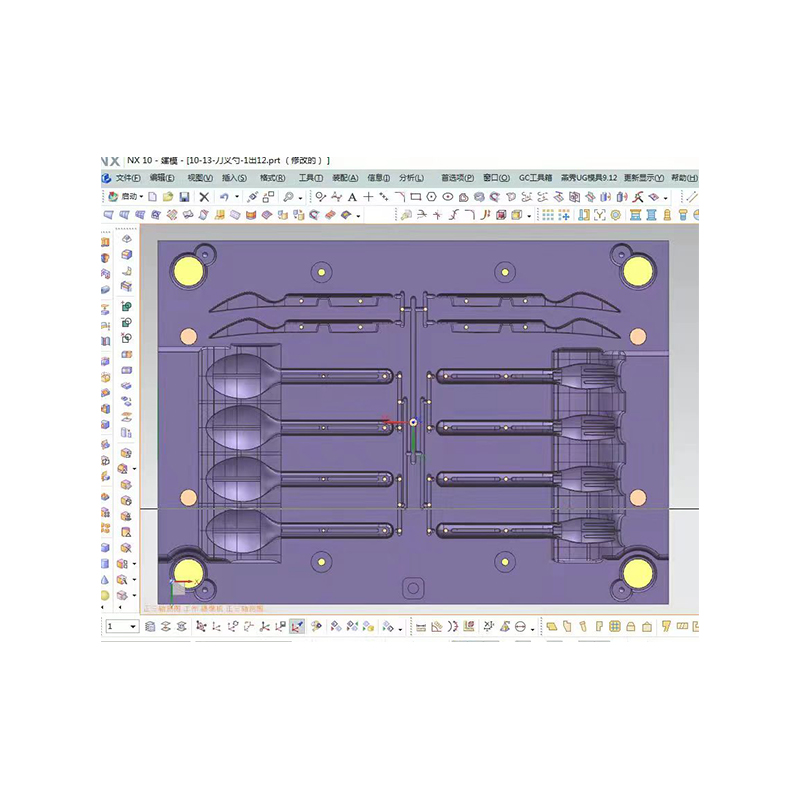

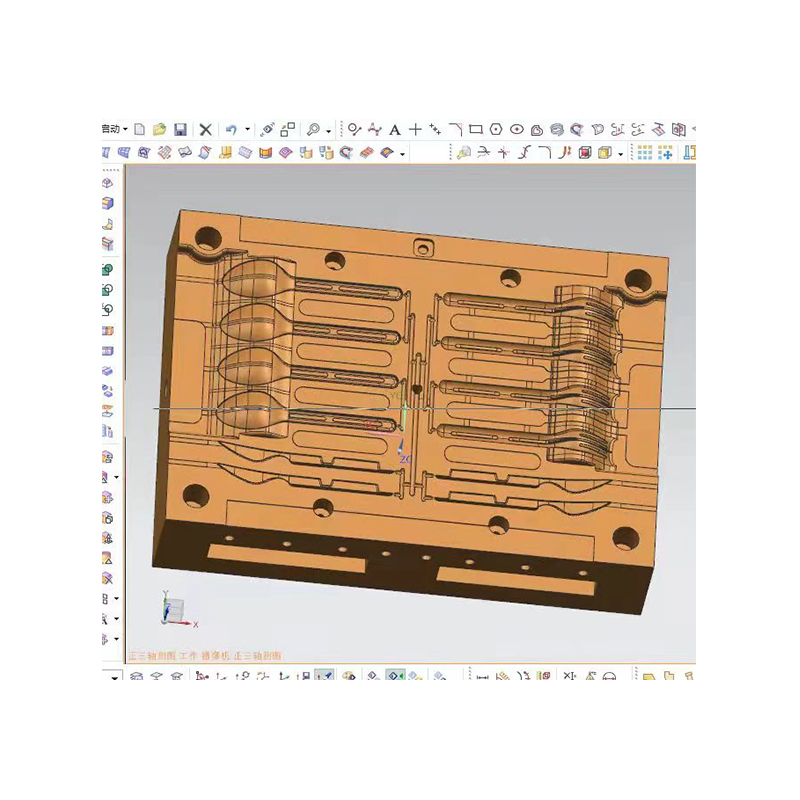

Versatility in Design: Multi-cavity cutlery mould offer versatility in design, accommodating various cutlery shapes and sizes. Manufacturers can create mould with different cavity configurations to produce a wide range of cutlery items, such as forks, knives, and spoons. This adaptability allows for greater flexibility in product offerings and customization.

The Role of Plastic Injection mould in Modern Industrial Manufacturing

Plastic Injection Mould Factory, including multi-cavity mould, play a pivotal role in modern industrial manufacturing. Their influence extends across various industries, providing solutions that enhance efficiency, precision, and scalability.

Precision and Accuracy: Plastic Injection Mould Factory are renowned for their ability to produce parts with high precision and accuracy. The moulding process involves injecting molten plastic into a mould cavity, where it cools and solidifies into the desired shape. This precision is essential for creating parts with tight tolerances and complex geometries, meeting the exact specifications required by various industries.

High-Volume Production: The use of Plastic Injection Mould Factory enables high-volume production of plastic components. The ability to produce large quantities of parts quickly and efficiently makes injection moulding a preferred method for industries that require mass production, such as automotive, consumer goods, and electronics. Multi-cavity mould further enhance this capability by allowing multiple parts to be produced in a single cycle.

Cost Efficiency: Plastic injection moulding offers cost advantages through its efficient production process. The initial investment in mould can be substantial, but the long-term benefits include reduced production costs and lower per-unit prices. The efficiency of the injection moulding process, combined with the durability and reusability of mould, contributes to overall cost savings.

Material Versatility: Plastic injection moulding accommodates a wide range of plastic materials, each with unique properties such as strength, flexibility, and resistance to heat or chemicals. This versatility allows manufacturers to select the suitable material for their specific applications, resulting in high-quality and functional products.

Complex Part Production: Plastic Injection Mould Factory enable the creation of complex and intricate parts that might be challenging or costly to produce using other manufacturing methods. The ability to incorporate detailed features, internal structures, and fine details within the mould design expands the possibilities for product design and innovation.

English

English Español

Español عربى

عربى