Product Description:

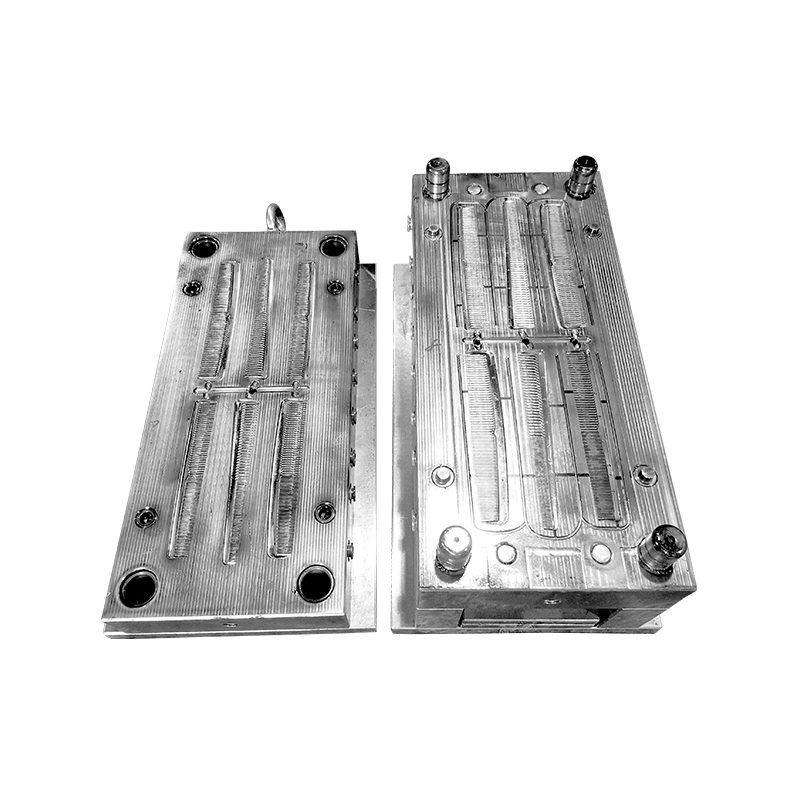

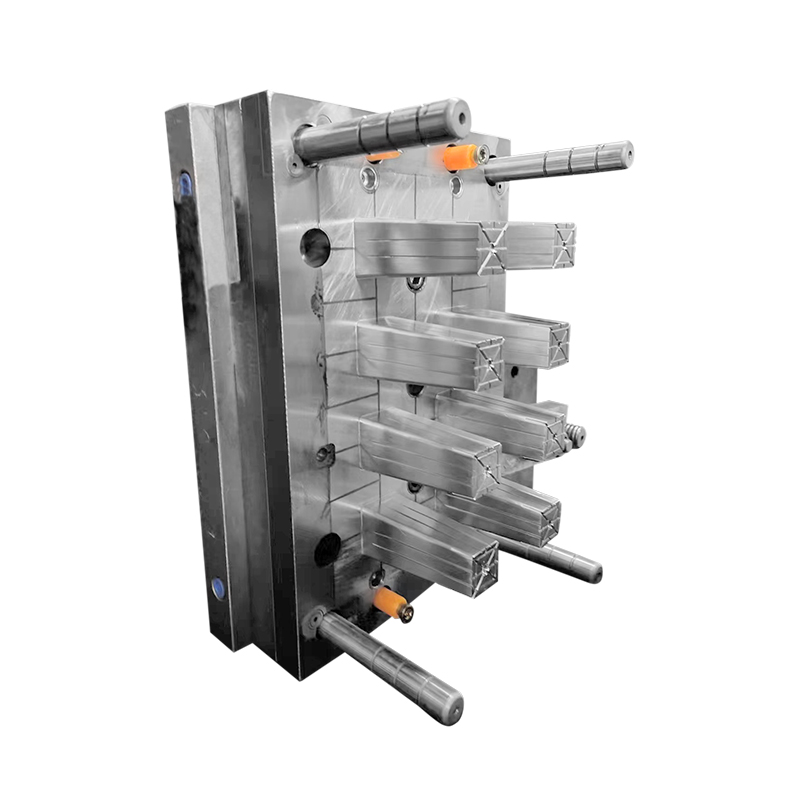

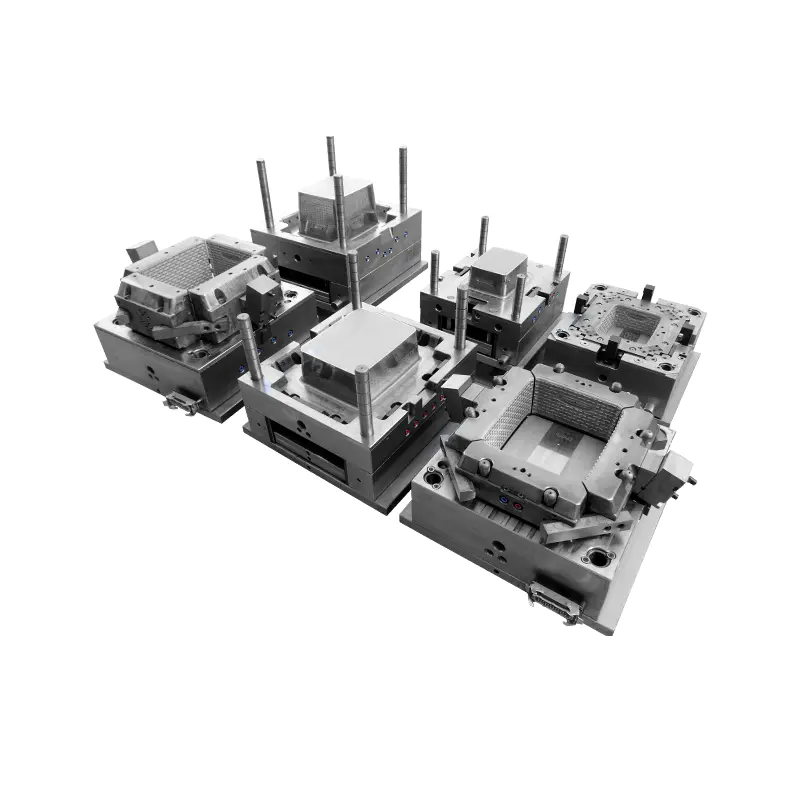

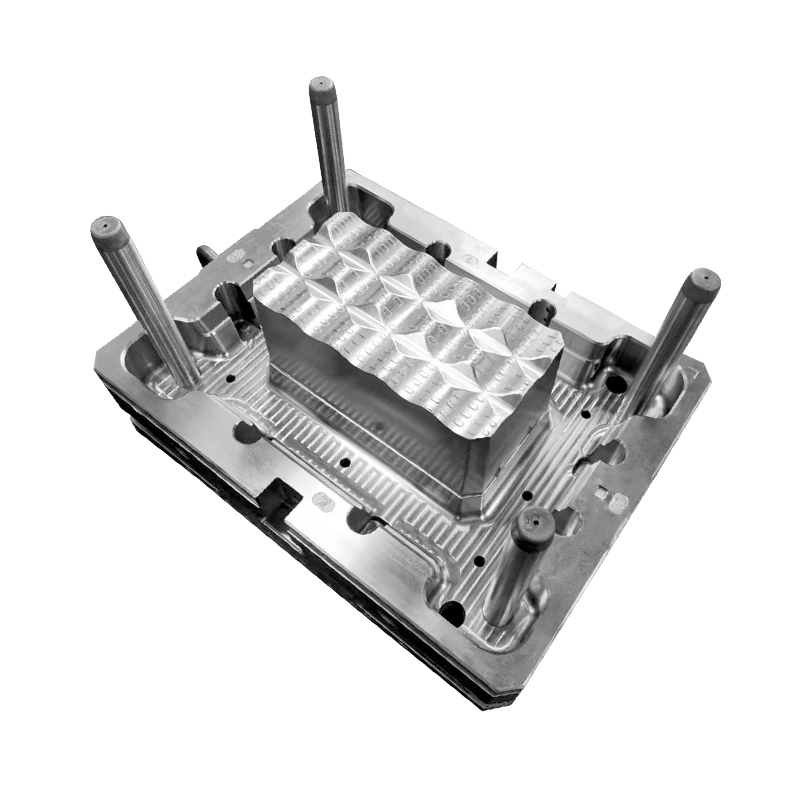

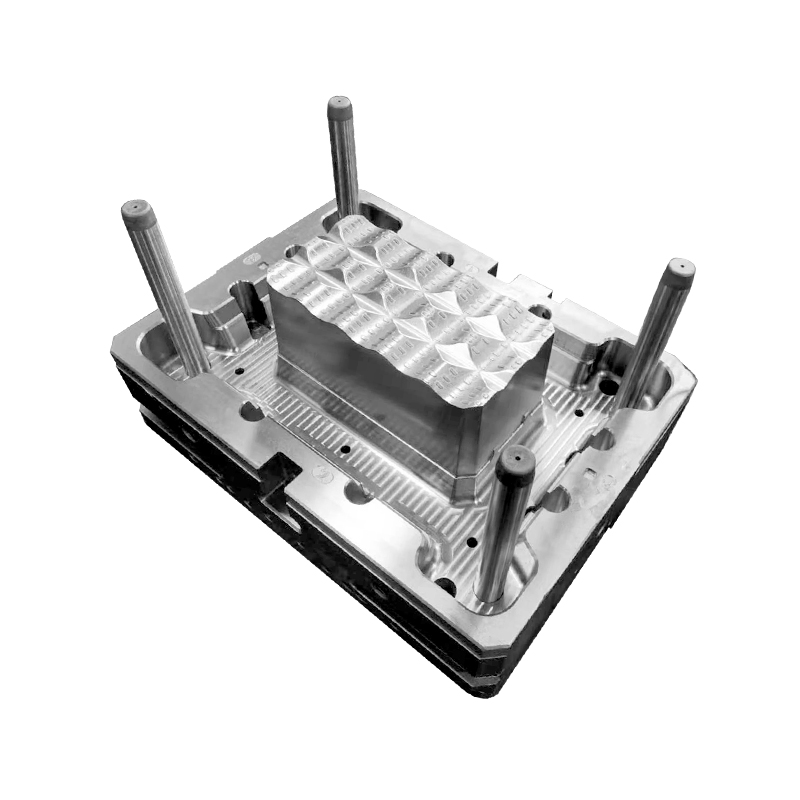

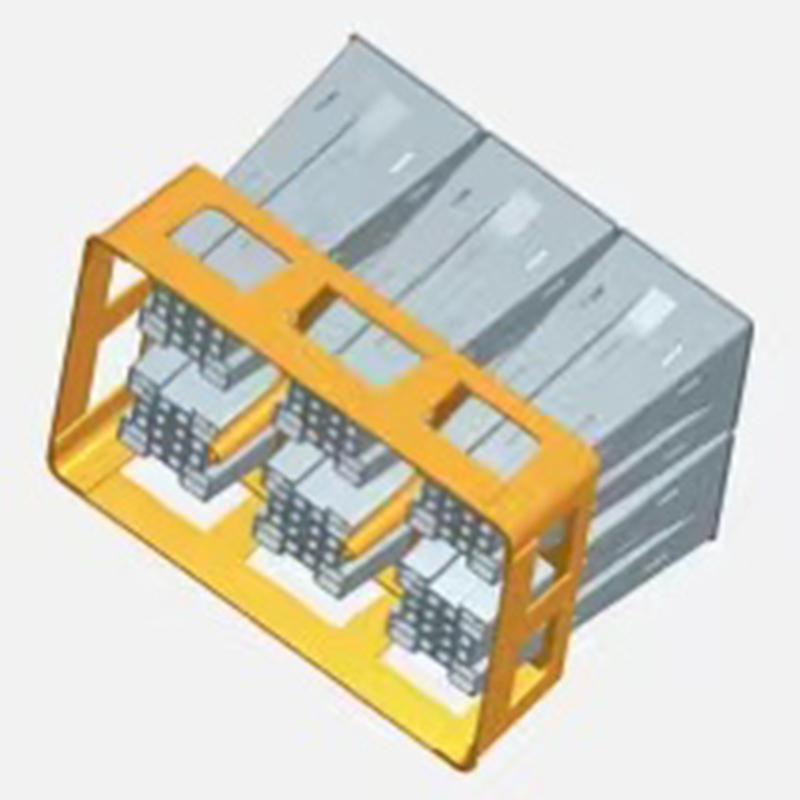

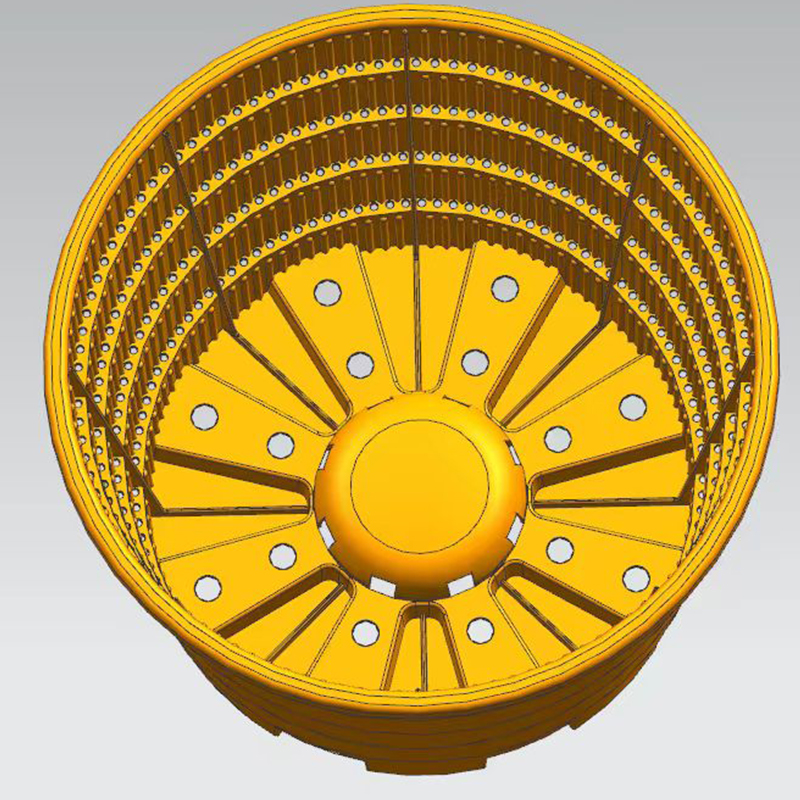

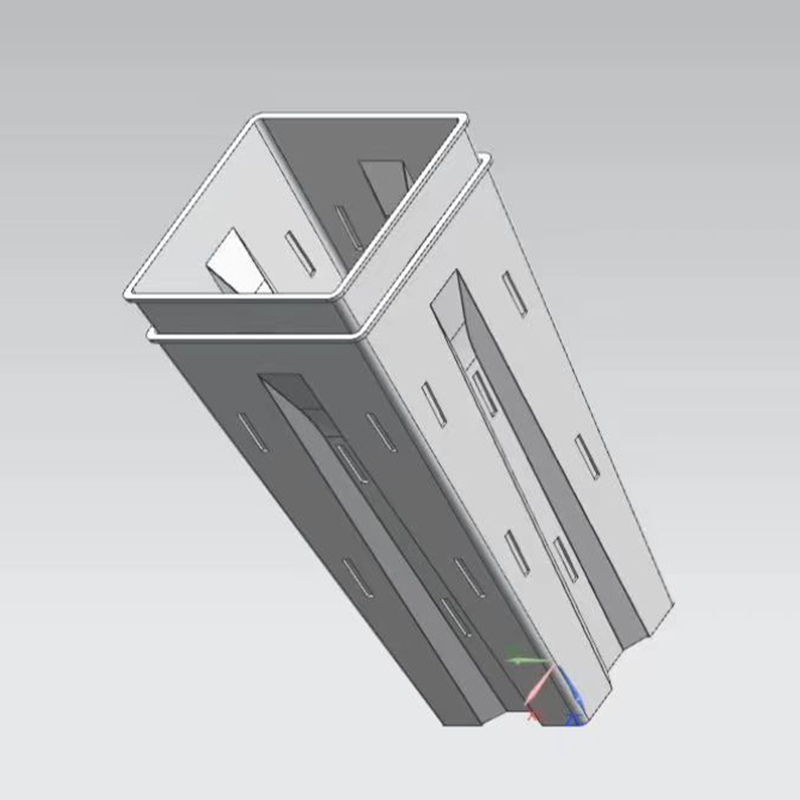

Our Food/Beverage Plastic Crate Mould is meticulously designed to meet the diverse needs of our clients across different industries.

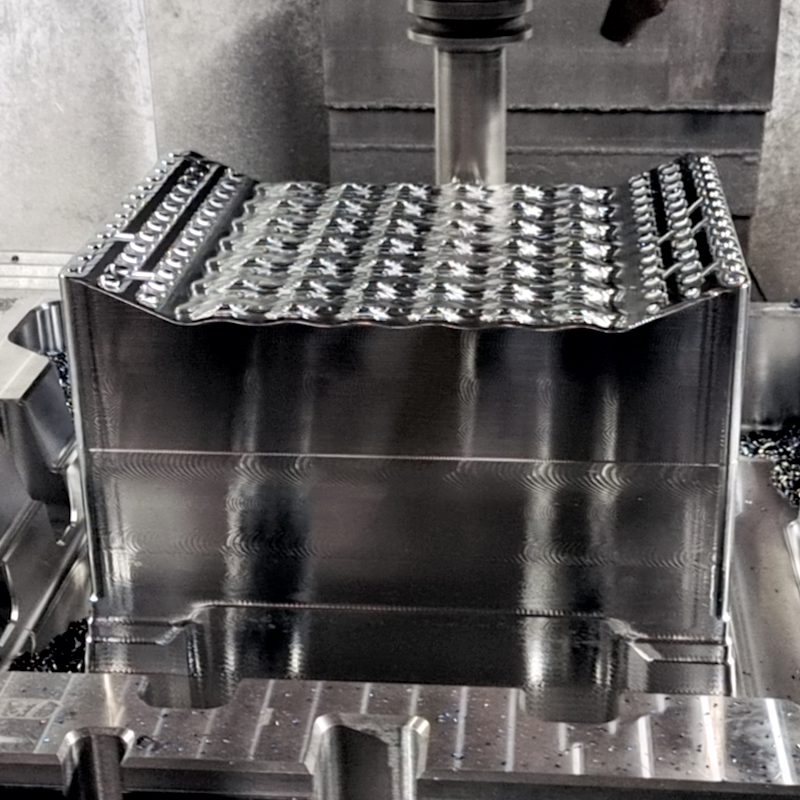

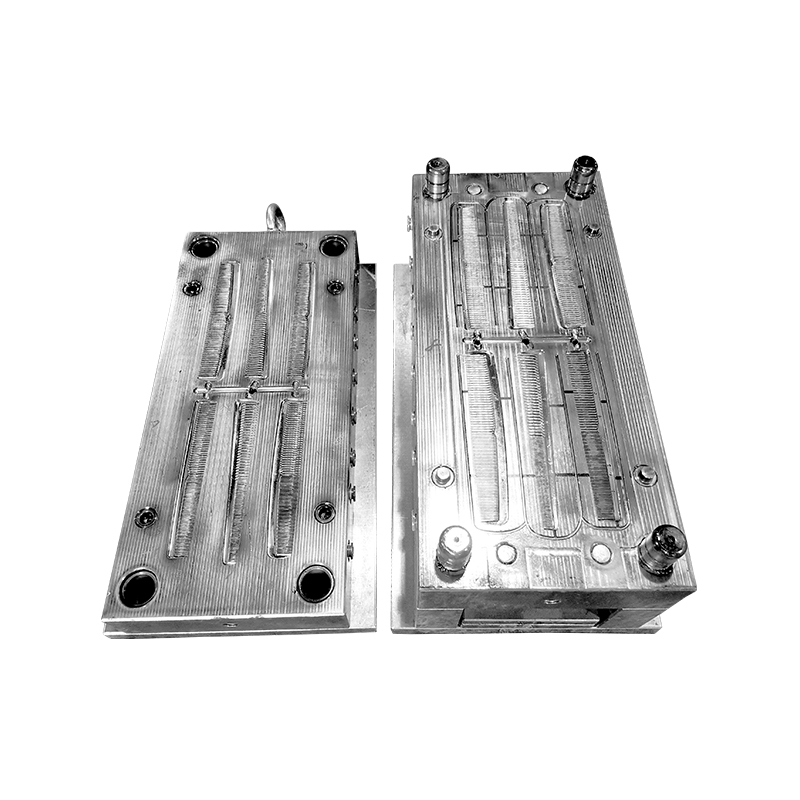

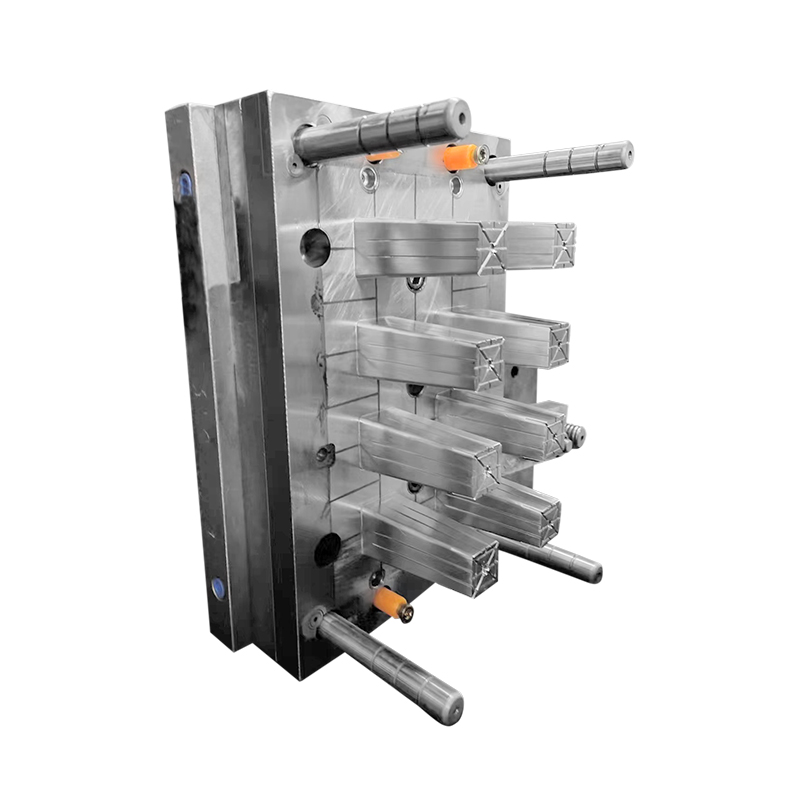

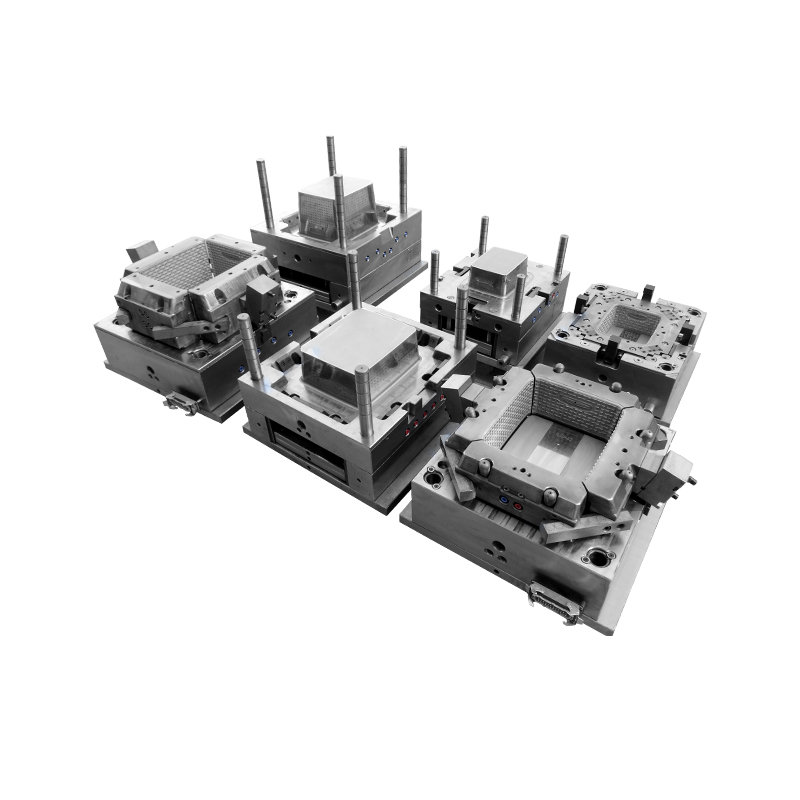

Household moulds, also known as moulds, are instrumental in the manufacturing process of a wide array of household items. These moulds are typically made from materials like steel, aluminium, or even silicone, depending on the specific requirements of the product being manufactured. They serve as the negative impression of the desired object, into which molten material is injected, cooled, and solidified to take its final form.

Applications of Household Moulds:

The applications of household moulds are vast and varied, encompassing al every aspect of domestic life. Here are some common areas where household moulds find extensive use:

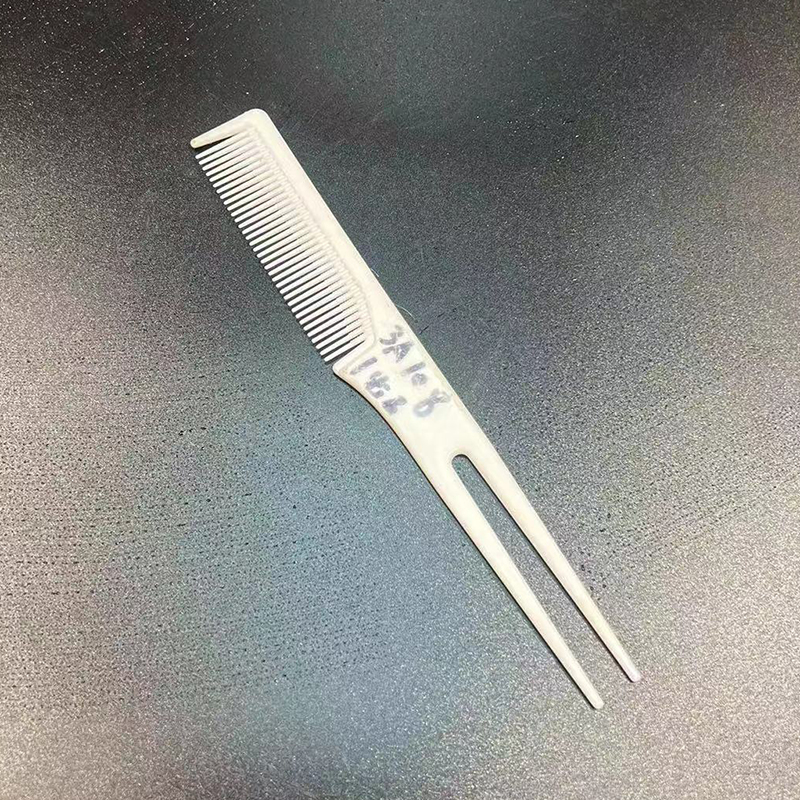

Kitchenware:

From utensils to storage containers, household moulds play a crucial role in the production of various kitchen essentials. Items like plastic containers, cutlery, and even intricate baking moulds owe their existence to these moulding techniques.

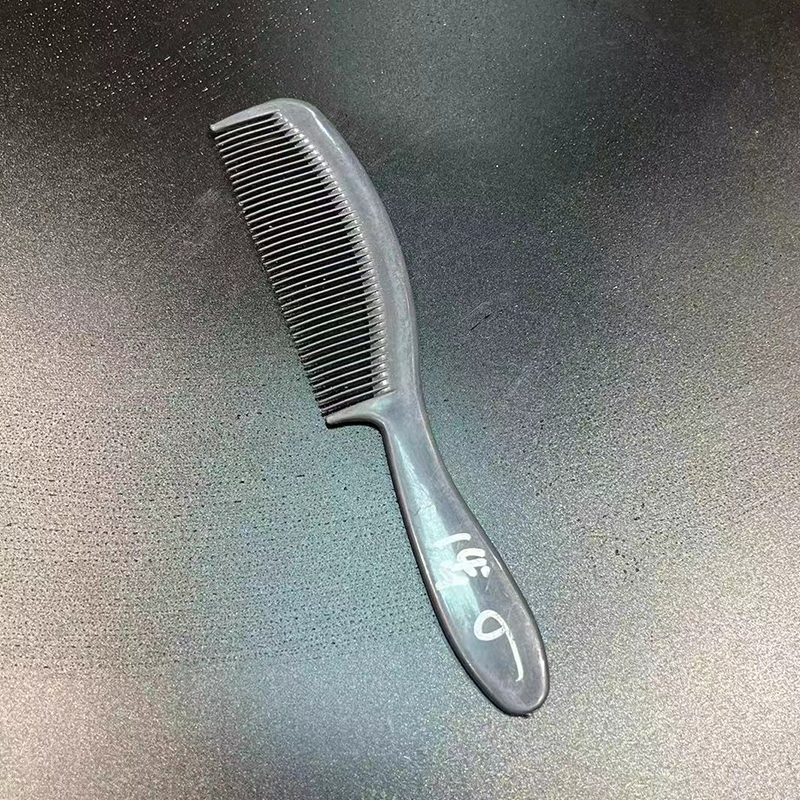

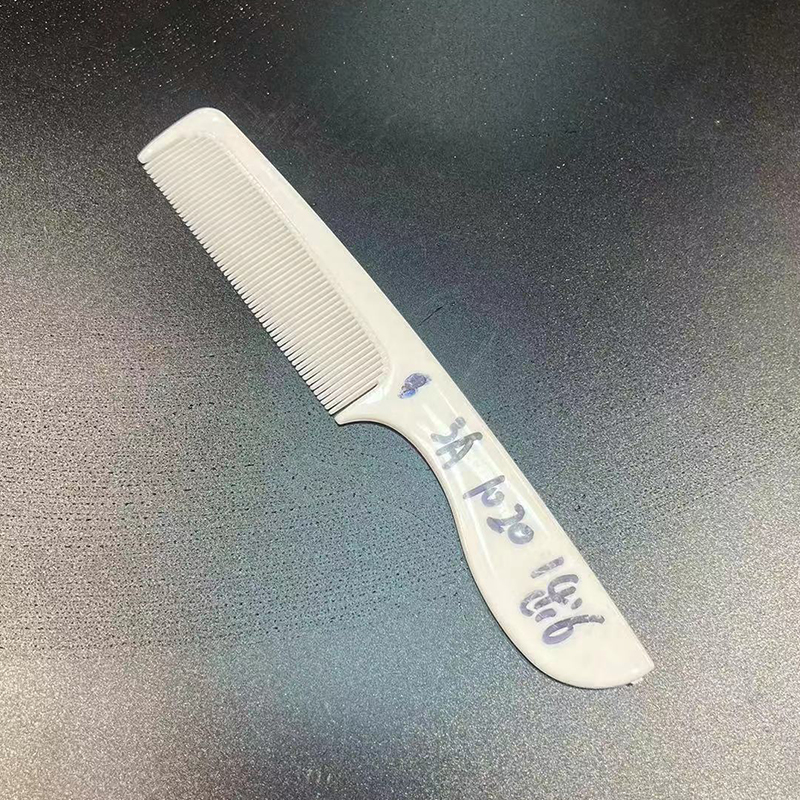

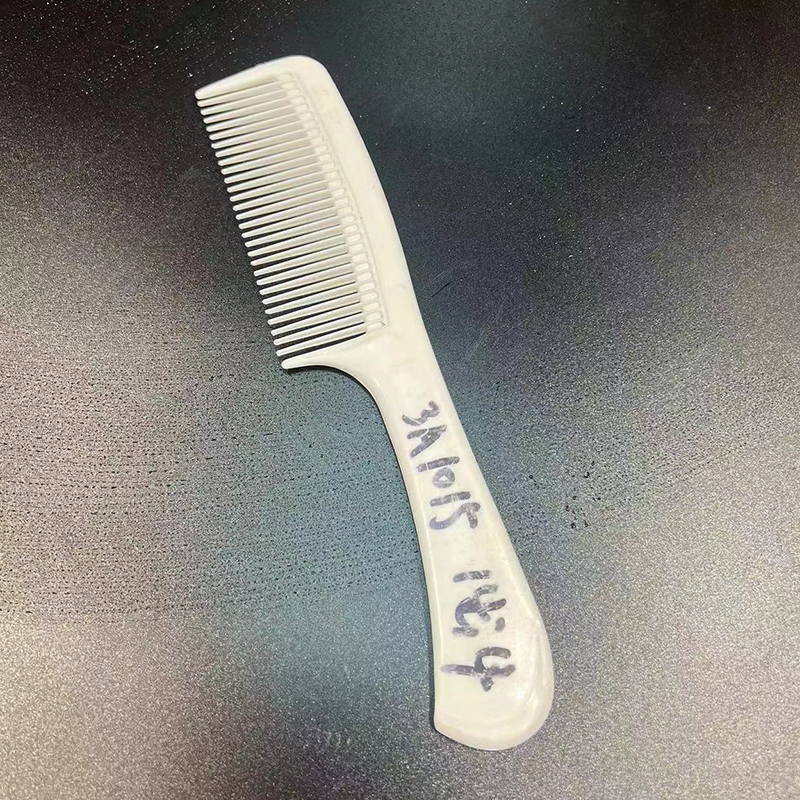

Bathroom Accessories:

Household moulds are also integral to the manufacturing process of bathroom accessories such as soap dishes, toothbrush holders, and shower caddies. Their ability to replicate intricate designs ensures that these products not only serve their functional purpose but also enhance the aesthetics of the space.

Home Décor:

Many decorative items found in homes, including picture frames, candle holders, and decorative figurines, are crafted using household moulds. These moulds enable manufacturers to replicate intricate designs and textures, allowing homeowners to add a personal touch to their living spaces.

Storage Solutions:

From plastic bins to organizers and drawer dividers, household moulds are indispensable in the production of various storage solutions that help homeowners keep their spaces tidy and organized.

Advantages of Household Moulds:

The use of household moulds offers several advantages, both for manufacturers and consumers alike:

Precision and Consistency:

Household moulds allow for the precise replication of intricate designs, ensuring consistency in the final products. This precision is essential, especially for items that require tight tolerances and exact specifications.

Material Flexibility:

Household moulds can accommodate a variety of materials, including plastics, metals, and even composites, depending on the requirements of the end product. This flexibility enables manufacturers to choose materials that offer the desired properties, such as durability, flexibility, or heat resistance.

Design Freedom:

Home moulds offer designers unparalleled freedom to create complex shapes.

Household mould plays a vital role in various aspects of modern living, from manufacturing essential household items to providing indispensable services in food preservation and waste management. The diverse applications, production processes, services, and advantages associated with household mould underscore its significance in everyday life.

English

English Español

Español عربى

عربى