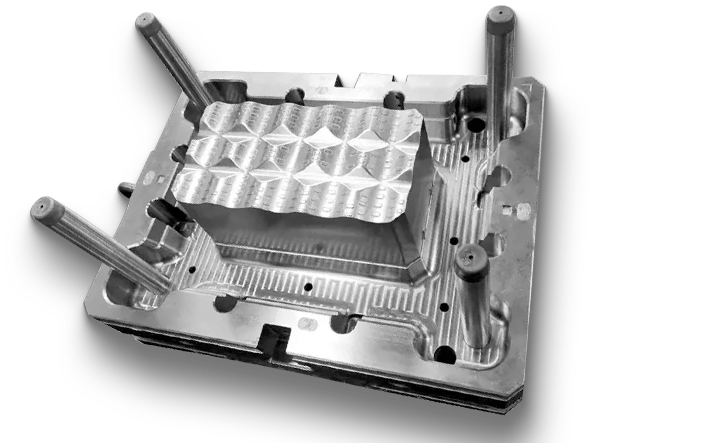

The Plastic Thin Space Cup Mould represents an innovation in the manufacturing o...

-

+86-15068654601

-

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

+86-15068654601

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

What Is IML (In-Mould Labelling) Technology?

IML, or In-Mould Labelling, is a process used to apply labels directly onto the surface of plastic containers during the moulding process. In this method, pre-printed labels are placed inside the mould before the plastic is injected, which fuses the label with the container material. This creates a permanent bond between the label and the container, making it highly resistant to wear, fading, and peeling.

Process Overview: The IML process begins with placing a label, which may be made from paper, plastic, or other materials, into the mould cavity. The mould is then closed, and molten plastic is injected into the cavity, embedding the label into the surface of the container. The result is a container with a fully integrated label that is part of the plastic itself.

Benefits of IML: IML provides an efficient and cost-effective way to incorporate high-quality graphics, logos, and branding onto containers. Since the label becomes part of the container, there is no need for additional adhesive, which can reduce costs and environmental impact. The result is a container with a sleek, durable appearance that maintains its aesthetic appeal over time.

How Does IML Technology Contribute to Anti-Theft Features?

The integration of anti-theft features into food containers using IML technology has become an important development in the fight against food theft in commercial settings, such as cafeterias, supermarkets, and vending machines. By combining labelling and security features, these containers help prevent theft and increase traceability.

Security Integration: The IML moulds for anti-theft food containers can incorporate various security features, such as unique barcodes, serial numbers, or tamper-evident labels. These features make it more difficult for thieves to steal or counterfeit the containers. For example, a tamper-evident label embedded in the mould during the manufacturing process would show visible signs of damage if anyone attempted to open the container without permission.

Branding and Traceability: Additionally, the use of IML enables branding that is difficult to remove or alter. By embedding the label directly into the container, it's much harder to replace or counterfeit, adding an extra layer of security to the product. This integration helps businesses track their products more effectively, especially when paired with digital tracking systems, which can deter theft and ensure the authenticity of each item.

What Are the Advantages of Using IML Anti-Theft Food Container Moulds?

IML anti-theft food container moulds offer several advantages, particularly in the realms of security, durability, and cost efficiency. These benefits help improve both consumer satisfaction and operational efficiency for manufacturers.

Enhanced Durability and Security: One of the main advantages of IML food containers is their durability. Since the label is embedded directly into the container, it becomes resistant to fading, peeling, and scratching. This results in containers that remain visually appealing and secure throughout their lifecycle. The tamper-evident features also offer an additional layer of protection against theft, ensuring that the contents of the container are not accessed without detection.

Improved Brand Recognition: IML allows businesses to apply intricate designs, logos, and branding directly onto the food containers. This not only enhances the aesthetic appeal but also improves brand recognition. Consumers are more likely to trust and purchase products from brands they recognize, and the high-quality finish of IML labels further strengthens this perception.

Cost Efficiency and Sustainability: The IML process is cost-efficient because it eliminates the need for separate labelling, which can be time-consuming and costly. Additionally, the reduction in the use of adhesives and paper labels makes IML a more sustainable option, aligning with the growing demand for environmentally friendly packaging solutions.

Where Are IML Anti-Theft Food Container Moulds Commonly Used?

IML anti-theft food container moulds are widely used in a variety of industries where security and durability are essential. These containers are particularly valuable in situations where products need to be kept secure and visible, especially in settings prone to theft or contamination.

Food Service and Retail: One of the most common applications for IML anti-theft food containers is in the food service industry. Cafeterias, supermarkets, and food vending machines often require secure, tamper-evident packaging for food items to prevent theft or tampering. IML containers are commonly used for ready-to-eat meals, snacks, and beverages, as they are durable, easy to handle, and offer visible branding. The anti-theft features also provide an added level of protection against product theft in high-traffic areas.

Pharmaceuticals and Consumer Goods: In addition to the food industry, IML anti-theft containers are also used in pharmaceuticals and consumer goods sectors. These containers help ensure that products are not tampered with and that customers receive items in their original, secure state. The tamper-evident labels are particularly important in pharmaceuticals, where the integrity of the product is vital for consumer health.

Packaging for High-Value Products: High-value products, such as specialty beverages, gourmet foods, or luxury items, can also benefit from IML anti-theft packaging. In these cases, the combination of attractive design and anti-theft features enhances both security and product appeal.