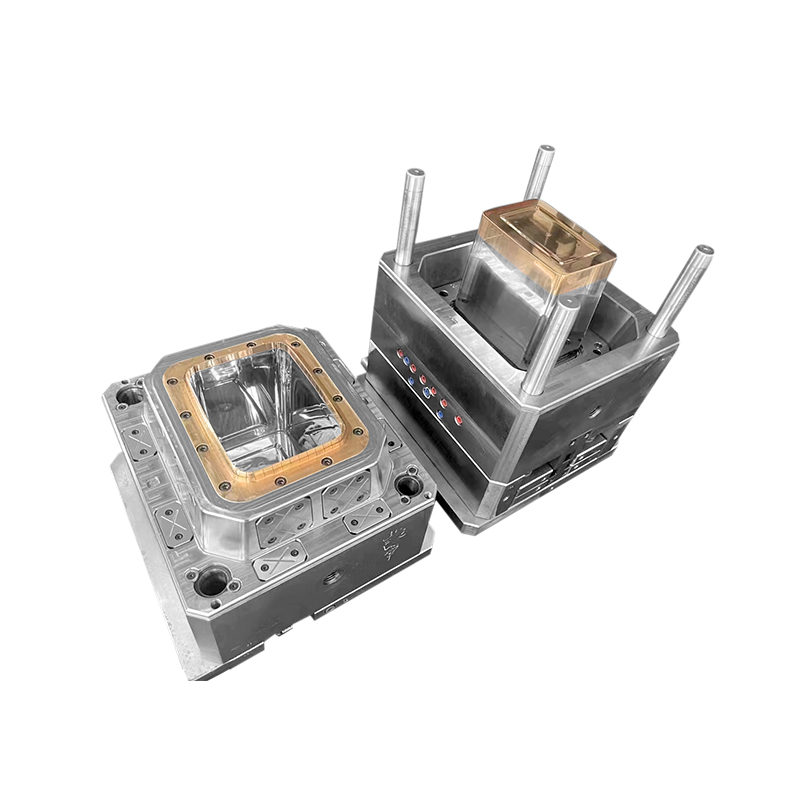

The Plastic Thin Space Cup Mould represents an innovation in the manufacturing o...

-

+86-15068654601

-

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

+86-15068654601

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

In-mold labeling is a process where a pre-printed label is inserted into a mold cavity during the molding process of a plastic container. As the plastic is injected into the mold, it fuses with the label, creating a seamless, durable bond. The result is a container with a high-quality, professional finish that resists wear and tear. The IML technique has become especially popular for food containers due to its ability to offer intricate designs while maintaining hygiene standards.

The concept of "anti-theft" in the context of IML food containers refers to integrating features into the mold design that make the containers more resistant to tampering or theft. This could include physical alterations like security tags or embedded identification codes that make it easier to track or authenticate the product.

Key Design Considerations for IML Anti-Theft Food Container Molds

Designing an IML anti-theft food container mold involves careful attention to several factors to ensure both functional and aesthetic requirements are met. Below are the key considerations that influence the mold design:

1. Material Selection

The choice of material for both the mold and the food container plays a critical role in the container’s durability, safety, and effectiveness. Food-grade plastic materials, such as polypropylene (PP), polyethylene (PE), or PET, are typically used due to their ability to withstand the molding process and provide a strong, long-lasting product.

Food-Safe Materials: The materials selected for the mold must comply with regulatory standards for food safety. They should be non-toxic and capable of handling direct contact with food products without leaching harmful chemicals.

Durability: The mold should be designed with a material that ensures long-term use, especially for containers that need to maintain their shape and structure over time.

Anti-Tampering Properties: The selected material for the mold and the food container must resist manipulation or damage, enhancing the container's resistance to theft or tampering.

2. Integration of Anti-Theft Features

The introduction of anti-theft features within the IML mold design adds a layer of security to the food container. The design must incorporate elements that make the container harder to steal or tamper with without being too intrusive or affecting the user experience.

Security Tags or RFID: Some IML molds are designed to incorporate security tags or RFID chips into the container. These tags allow for tracking and monitoring, which can help prevent theft or unauthorized handling.

Tamper-Evident Features: Molds can be designed to create tamper-evident seals that make it clear if the container has been opened or altered. These features may include breakable seals or specialized locking mechanisms that secure the lid to the base of the container.

Embedded Codes or Watermarks: Invisible or hard-to-reproduce markings such as QR codes, barcodes, or holograms can be integrated into the mold design. These markings can serve as proof of authenticity or help with inventory tracking.

3. Precision and Detail in the Mold Design

IML molding requires a high level of precision, as the quality of the final product depends heavily on the accuracy of the mold. The design of the mold must ensure that the plastic good fits into the label, creating a seamless, durable product.

High-Precision Molds: The mold must be carefully crafted with exact tolerances to ensure a good fit for both the plastic material and the embedded label. This level of precision is crucial to avoid defects or weak spots in the container, which could potentially compromise its anti-theft features.

Label Alignment: The mold design needs to ensure that the label is precisely aligned with the container, as any misalignment can poor appearance or compromised structural integrity.

Enhanced Surface Finish: The final product should have a smooth, clean finish that resists scratching, which could expose underlying security features.

4. Mold Durability and Longevity

The durability of the mold itself is a significant factor in ensuring that the IML anti-theft food containers are produced consistently over a long period. Molds that are frequently used in mass production need to maintain their precision and functionality for thousands of cycles.

High-Quality Mold Materials: The material of the mold must be able to withstand the intense pressure and temperatures involved in the molding process. Hardened steel or other robust alloys are typically used for high-durability molds.

Wear Resistance: Molds that include intricate anti-theft features, such as RFID pockets or security seals, need to be designed with materials that prevent wear and tear over time, ensuring that these features remain functional through many cycles.