The Plastic Thin Space Cup Mould represents an innovation in the manufacturing o...

-

+86-15068654601

-

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

+86-15068654601

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

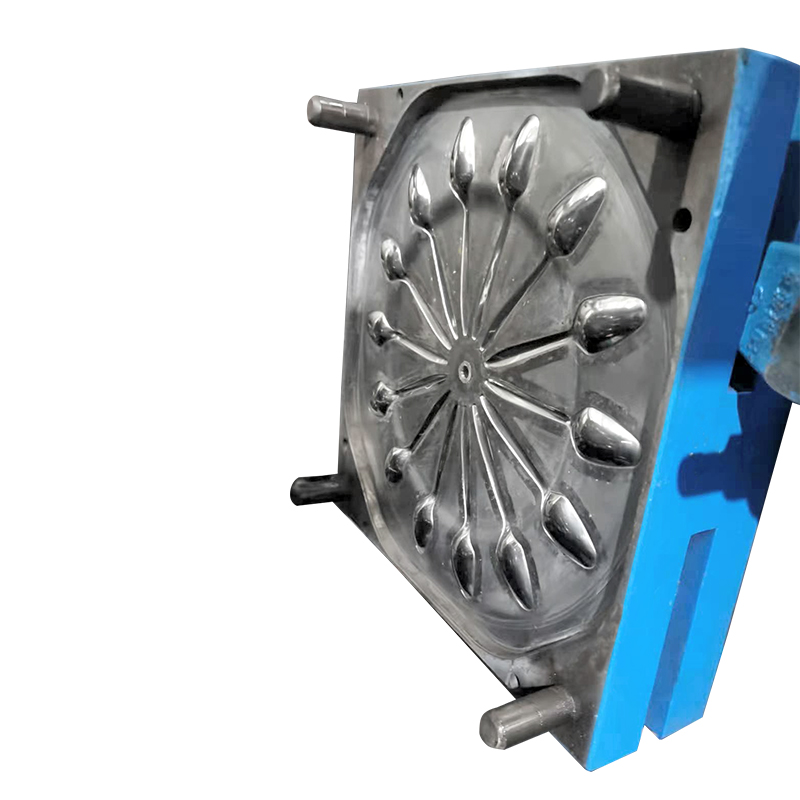

Multi-cavity cutlery molds manufacturer are essential tools in the mass production of plastic cutlery such as forks, spoons, and knives. These molds allow manufacturers to produce multiple pieces in a single injection cycle, improving efficiency and consistency.

Key Characteristics of Multi-Cavity Cutlery Molds

Multi-cavity cutlery molds have several defining features that differentiate them from single-cavity or simpler molds. These characteristics contribute to high-volume production and uniform product quality.

Multiple cavities: As the name suggests, multi-cavity molds contain several cavities within a single mold frame. This allows multiple cutlery pieces to be produced simultaneously, significantly reducing cycle time and increasing production output. The number of cavities can vary depending on the size of the cutlery and the machine capacity, typically ranging from four to sixteen cavities or more.

Precision and uniformity: High-quality multi-cavity molds are designed to maintain uniform thickness, dimensions, and surface finish across all cavities. This precision ensures that every cutlery piece meets quality standards and reduces waste due to defective products.

Temperature control: These molds often incorporate built-in cooling channels or systems to maintain consistent temperature throughout the mold. Proper temperature management ensures uniform filling, prevents warping, and improves cycle times.

Ejection system: Multi-cavity molds include ejection mechanisms, such as ejector pins or plates, to remove the molded cutlery pieces efficiently. This feature minimizes manual handling, reduces production delays, and ensures the pieces are not damaged during extraction.

Durable construction: High-grade steel or other durable materials are typically used in multi-cavity cutlery molds. These materials resist wear and deformation, supporting long-term production and maintaining dimensional accuracy over time.

Flexibility in design: Some multi-cavity molds allow interchangeable inserts or adjustable cavity layouts. This enables manufacturers to produce different cutlery types or accommodate minor design changes without needing a completely new mold.

These characteristics collectively ensure that multi-cavity molds are reliable, efficient, and capable of producing high-quality cutlery in large quantities.

Material and Design Considerations

The materials used in mold construction and design features play a significant role in performance and longevity.

Steel grade: Mold steel is commonly used for its strength, durability, and resistance to corrosion. High-quality steel ensures the mold withstands repeated injection cycles without deformation, maintaining dimensional accuracy over time.

Surface finish: Polished surfaces in the mold cavities prevent plastic adhesion and produce cutlery with smooth surfaces. Proper finishing reduces defects, eases demolding, and enhances the appearance of the final product.

Cooling and heating channels: Integrated cooling channels regulate the mold temperature, reducing cycle times and preventing warping or shrinkage. Some molds may also include heating elements to accommodate specific plastic materials or designs.

Ejection design: The placement and type of ejectors affect the efficiency and safety of removing cutlery pieces. Proper design ensures smooth ejection without causing scratches or deformation.

Modularity: Some molds offer modular designs with replaceable inserts or adjustable cavities, allowing manufacturers to switch between different cutlery shapes or sizes efficiently.

Selecting high-quality materials and design features ensures the mold’s reliability, extends its service life, and supports consistent production quality.

How to Select a Multi-Cavity Cutlery Mold

Choosing the right multi-cavity mold requires consideration of production requirements, material compatibility, and machine capacity.

Production volume: High-volume operations benefit from molds with more cavities to maximize output per cycle. For smaller production runs, molds with fewer cavities may be more cost-effective.

Cutlery design and size: The mold must accommodate the dimensions and shapes of the intended cutlery. Complex designs may require specialized cavity layouts or adjustable inserts.

Material compatibility: Different plastics, such as polypropylene, polystyrene, or biodegradable polymers, may require specific mold temperature settings or surface finishes. Ensure the mold is compatible with the chosen material.

Machine capacity: The mold size, weight, and injection requirements must match the capabilities of the injection molding machine. Oversized molds can operational inefficiencies or equipment strain.

Maintenance and durability: Select molds made from durable materials with well-designed cooling and ejection systems. Consider ease of maintenance, including cleaning and part replacement.