The Plastic Thin Space Cup Mould represents an innovation in the manufacturing o...

-

+86-15068654601

-

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

+86-15068654601

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

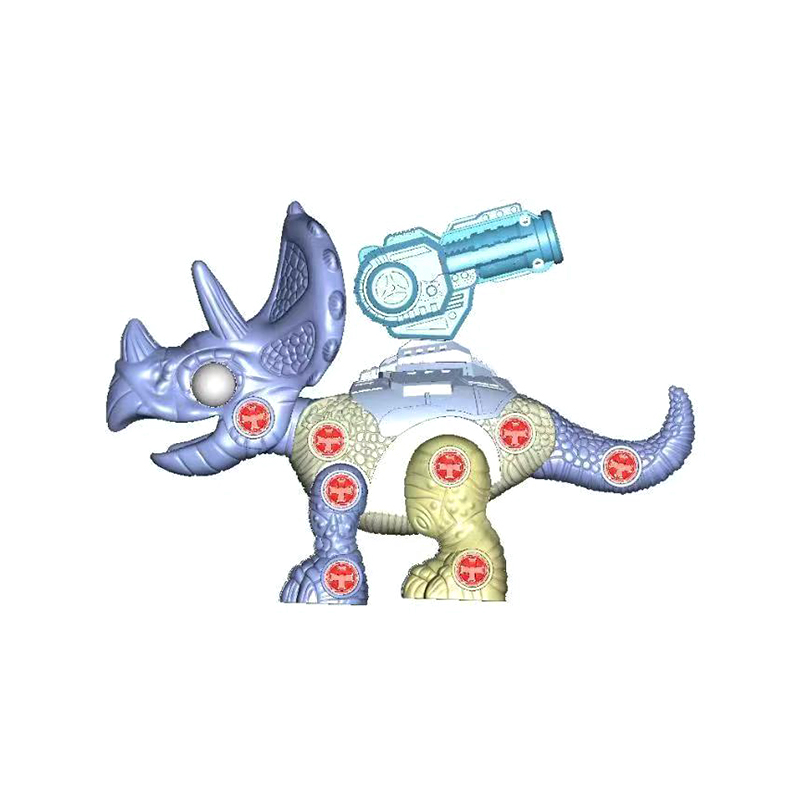

The plastic dinosaur toy injection mould, typically made from hardened tool steel, consists of two main halves and numerous internal mechanisms.

Mould Base: This is the structural frame, comprising a fixed half (cavity side, attached to the stationary platen of the injection machine) and a moving half (core side, attached to the moving platen). It includes guide pins and bushings for precise alignment.

Cavity and Core Inserts: These are the machined steel blocks that form the toy's shape. The cavity insert creates the dinosaur's outer surface and texture. The core insert forms the inner hollow surface and any internal features. For dinosaurs, these are often highly detailed.

Sprue, Runners, and Gates: This is the flow path for molten plastic. The sprue is the main channel from the machine nozzle. Runners distribute plastic to each cavity in multi-cavity moulds. Gates are small, controlled openings where plastic enters the actual cavity.

Cooling System: A network of drilled channels surrounding the cavity and core. Circulating temperature-controlled water through these channels solidifies the plastic quickly, determining the production cycle time.

Ejection System: This mechanism pushes the solidified toy out of the mould. It includes ejector pins (which contact the part), ejector plates, and return pins. For complex shapes like dinosaur tails, angled lifters may be used.

Slides and Cores: Movable steel sections that form undercuts, such as the open mouth of a Tyrannosaurus rex or the horns on a Triceratops. They retract at an angle before the main mould opens to release the part.

Vents: Thin channels at the parting line that allow trapped air to escape as plastic fills the cavity, preventing defects like burns or short shots.

The mould exists as a capital investment to enable the mass production of toys according to specific commercial and design needs.

Enabling High-Volume, Low-Cost Production

The primary reason is economic. Once the mould is built and installed, an injection moulding machine can produce a new dinosaur toy every 20 to 60 seconds. This high-speed, automated process allows for the manufacture of thousands of identical units per day, achieving a very low per-unit cost that makes inexpensive consumer toys feasible.

Replicating Intricate Detail Consistently

Dinosaur toys require specific, recognizable anatomical features—scales, claws, teeth, and skin textures. The mould cavity is machined and often chemically etched or laser-engraved to capture this detail. The mould ensures that every single toy produced is an exact, high-fidelity replica of the original sculpt, maintaining brand consistency and aesthetic quality.

Facilitating Part Assembly and Function

Many dinosaur toys are assembled from multiple moulded parts (head, body, limbs). The mould is engineered to produce parts with integral attachment features, such as cylindrical pegs and sockets for snap-fit assembly or rotating joints. It also forms the cavities for internal mechanisms, such as the gear housing for a walking or roaring action feature.

The manufacturing cycle is a repeated sequence of steps within an injection moulding machine.

Clamping: The two halves of the mould are hydraulically forced together and held under high pressure (clamping tonnage) to withstand the incoming injection pressure.

Injection: Plastic resin pellets (often polyethylene, polypropylene, or ABS) are fed from a hopper into a heated barrel. A rotating screw pushes the material forward, melting it. The screw then acts as a plunger, injecting the molten plastic under high pressure through the nozzle and into the mould's sprue, runners, gates, and cavities.

Cooling and Dwelling: Once the cavity is filled, the plastic begins to cool and solidify. The molten plastic in the runners also solidifies. During this dwelling phase, additional material may be packed into the cavity to compensate for shrinkage as the plastic cools. The cooling time is a major factor in the total cycle.

Mould Opening and Ejection: After a set cooling time, the clamping unit opens the mould. The moving half retracts, and the ejection system is activated. Ejector pins advance, pushing the solidified dinosaur part (and the attached runner system, called the sprue) off the core insert. Robots or operators then remove the assembly.

Post-Processing: The sprue and runners are trimmed from the dinosaur part. For multi-part toys, the components are collected and sent to an assembly line where they are snapped together, painted, and packaged. The mould then closes, and the cycle repeats.