The Plastic Thin Space Cup Mould represents an innovation in the manufacturing o...

-

+86-15068654601

-

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

+86-15068654601

No.62 Zhao Feng Road, Huangyan, Taizhou, Zhejiang, China

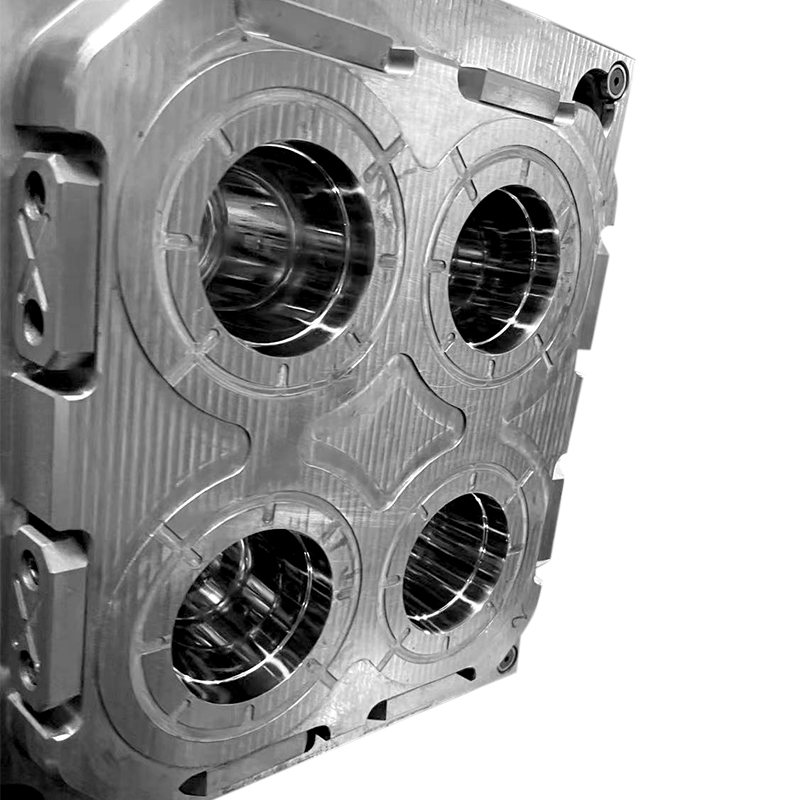

A mould, in injection molding, is the tool used to shape molten plastic into the desired product form. In the context of cutlery manufacturing, a multi-cavity mould is designed to produce several pieces of cutlery—such as forks, knives, or spoons—in a single injection cycle.

Unlike single-cavity moulds that produce one part at a time, multi-cavity moulds contain multiple identical cavities. For example, a mould may have 4, 8, 12, or even more cavities, enabling the simultaneous production of multiple cutlery items. This significantly increases output without proportionally increasing machine cycle time or labor.

The direct efficiency advantage of multi-cavity moulds is the increased production volume per cycle. Producing multiple cutlery pieces in one shot reduces the number of cycles required to meet production targets, effectively multiplying output.

For manufacturers, this translates into meeting large orders more quickly and reducing lead times. This advantage is particularly valuable during peak seasons or when fulfilling bulk orders.

By producing several parts simultaneously, manufacturers minimize the number of machine cycles needed. This means less frequent mold opening and closing, fewer part removal steps, and a more streamlined workflow on the production floor.

As a result, labor costs related to machine operation and part handling decrease. Additionally, shorter production times help extend the operational life of injection molding machines by reducing wear and tear associated with excessive cycling.

Multi-cavity moulds are engineered to maintain uniform cavity dimensions, ensuring that each cutlery piece produced is consistent in shape, size, and quality. This uniformity is crucial in packaging and presentation, where identical cutlery sets are expected.

Moreover, modern mould manufacturing techniques such as precision CNC machining and high-quality steel materials contribute to the durability and dimensional stability of multi-cavity moulds, further enhancing product quality consistency.

Producing multiple parts per cycle can bring about improved material utilization. By optimizing the runner system (the channels that guide molten plastic into cavities), manufacturers reduce plastic waste and minimize the need for trimming or reprocessing.

Additionally, higher production output per cycle means that the energy consumed by the molding machine is amortized over a larger number of products, effectively lowering energy costs per unit.

While multi-cavity moulds offer significant efficiency benefits, several factors influence their performance and suitability for different production scenarios:

The efficiency of a multi-cavity mould depends heavily on its design. Balanced filling of all cavities is essential to prevent defects such as short shots (incomplete filling) or uneven shrinkage. Advanced mold flow analysis is often used in the design phase to optimize gate placement and runner systems.

Additionally, proper cooling channel design ensures uniform cooling of all cavities, reducing cycle times and avoiding warping or distortion.

The injection molding machine must be capable of supplying sufficient injection pressure and volume to fill all cavities properly. Machines with insufficient tonnage or shot capacity may struggle with large multi-cavity moulds, bring about quality issues and inefficiencies.

Selecting the right machine that matches the mould's requirements is crucial for efficiency.

The type of plastic resin used influences how well the multi-cavity mould performs. Some materials flow more easily and can fill complex multi-cavity molds with less pressure, while others require more precise temperature and pressure controls.

Material consistency and drying prior to molding also affect cycle times and product quality.

Multi-cavity cutlery moulds are widely used in industries where disposable or reusable plastic cutlery is produced at scale, including food service, hospitality, and retail sectors. Their efficiency supports large-scale production needed to meet global demand while maintaining product quality and cost control.

Additionally, as sustainability concerns grow, manufacturers increasingly seek multi-cavity mould designs that reduce waste and enable the use of biodegradable or recycled materials, contributing to greener production practices.